PDC for Road Milling

Request a quote for detailed information (MOQ, price, delivery)

PDC for Road Milling :

From standard cutters to custom drilling solutions, we provide the industry's most reliable PDC products for extreme conditions.

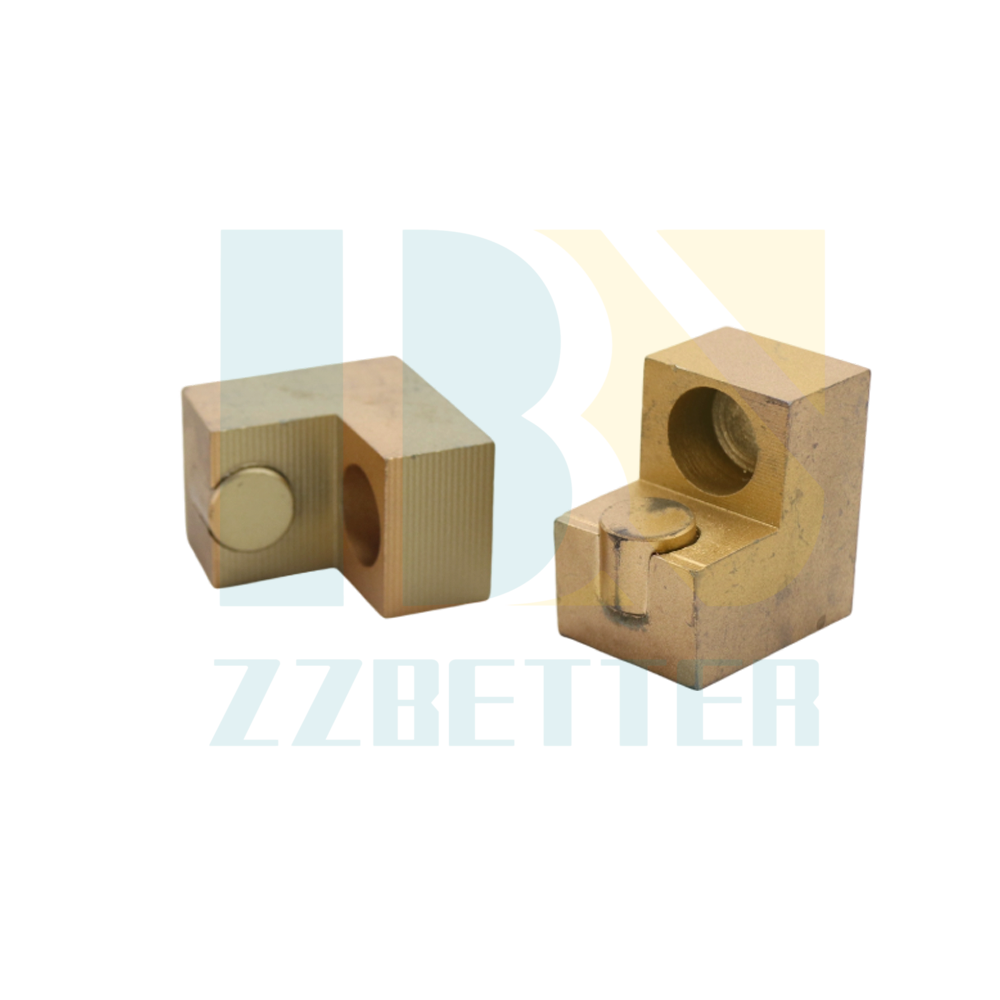

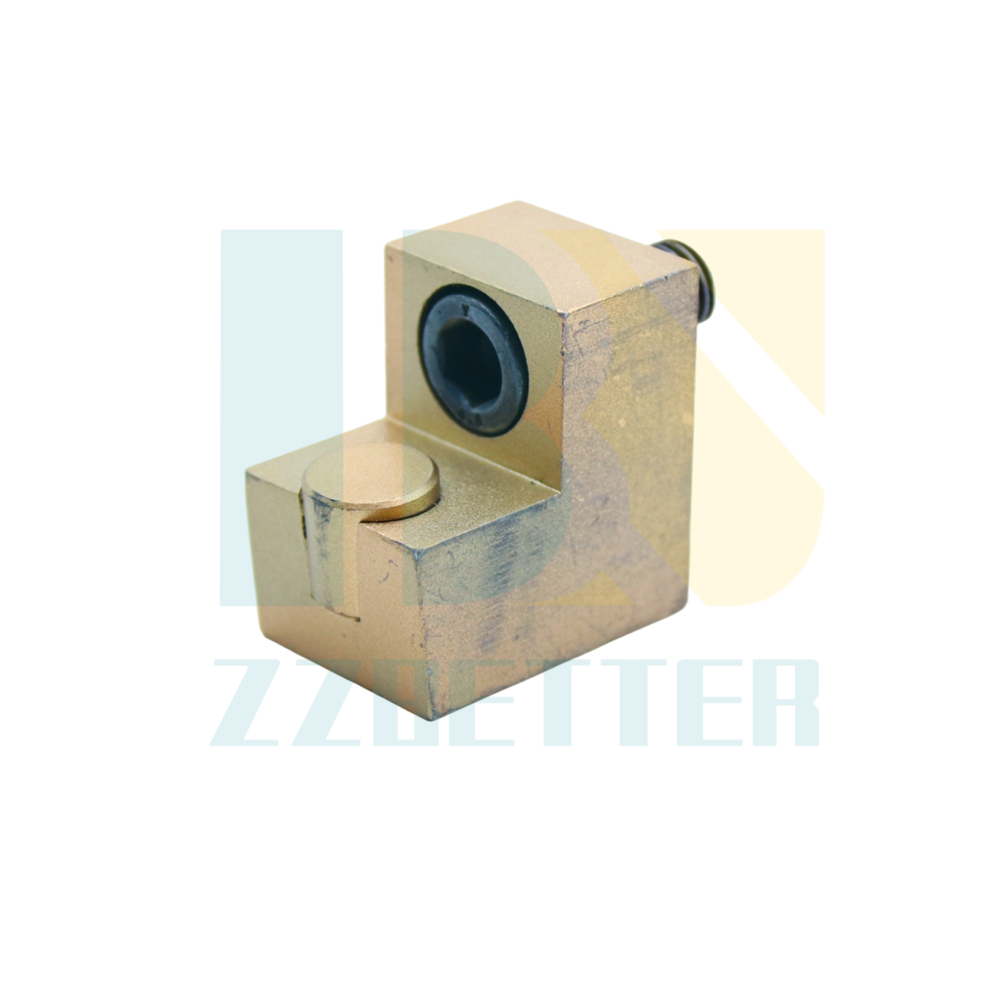

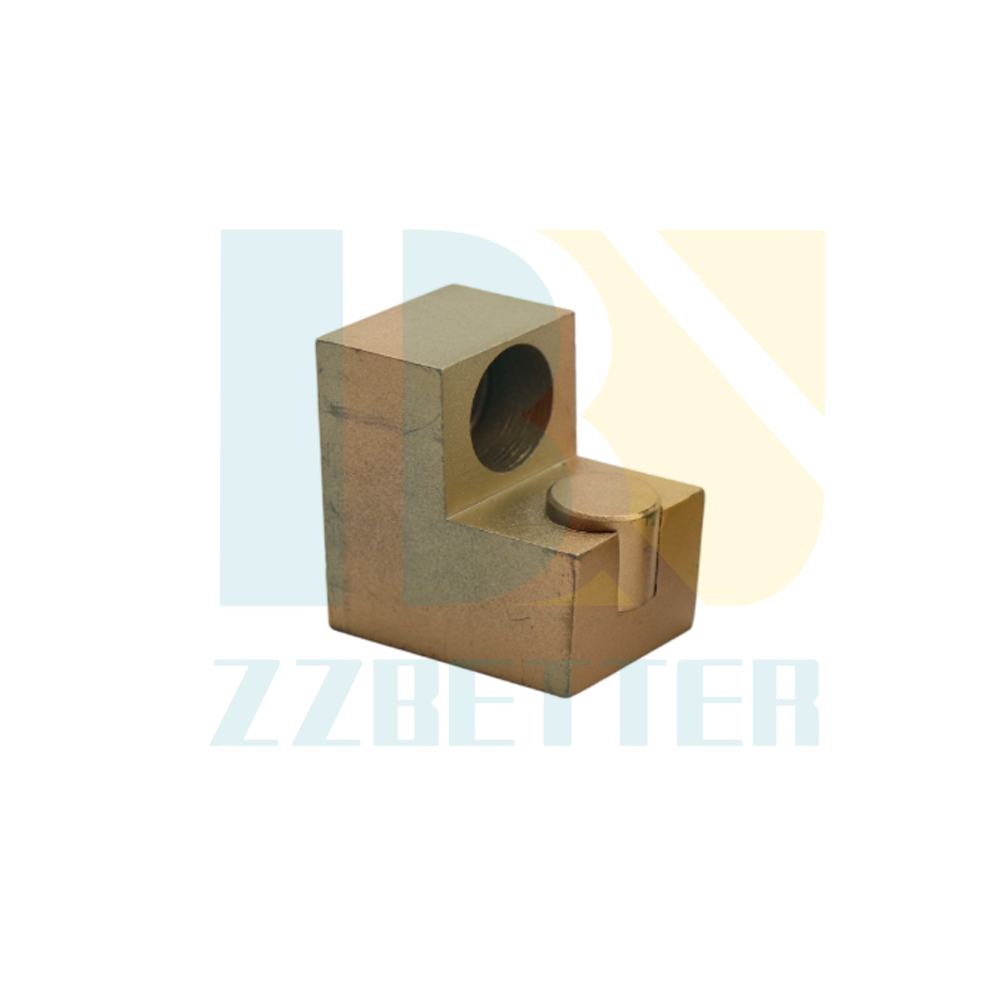

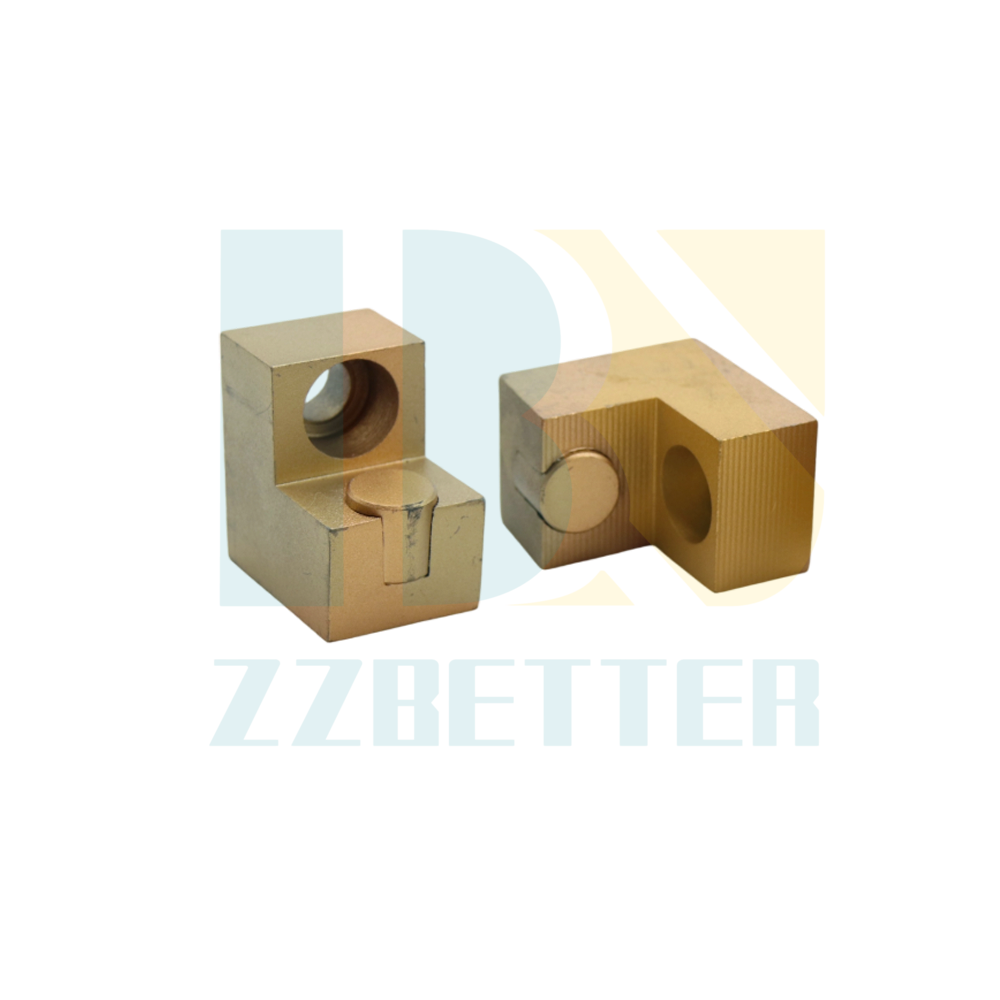

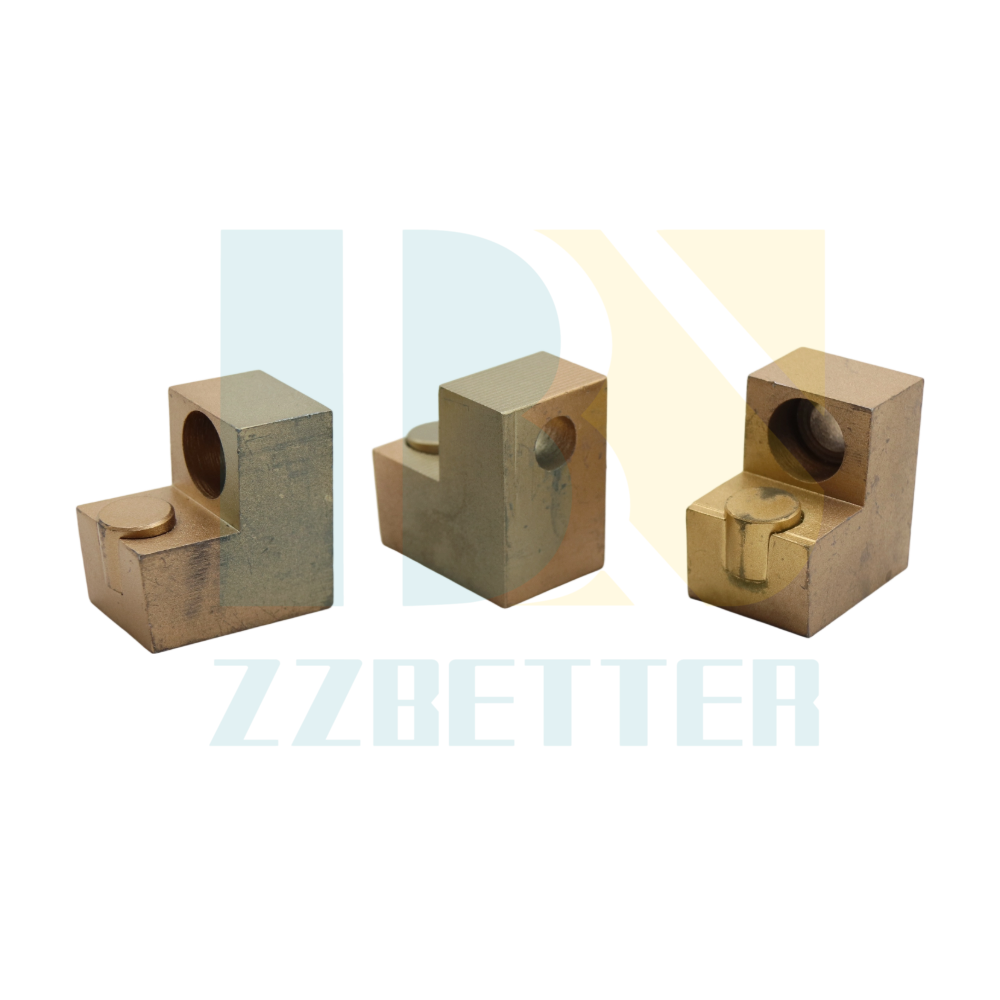

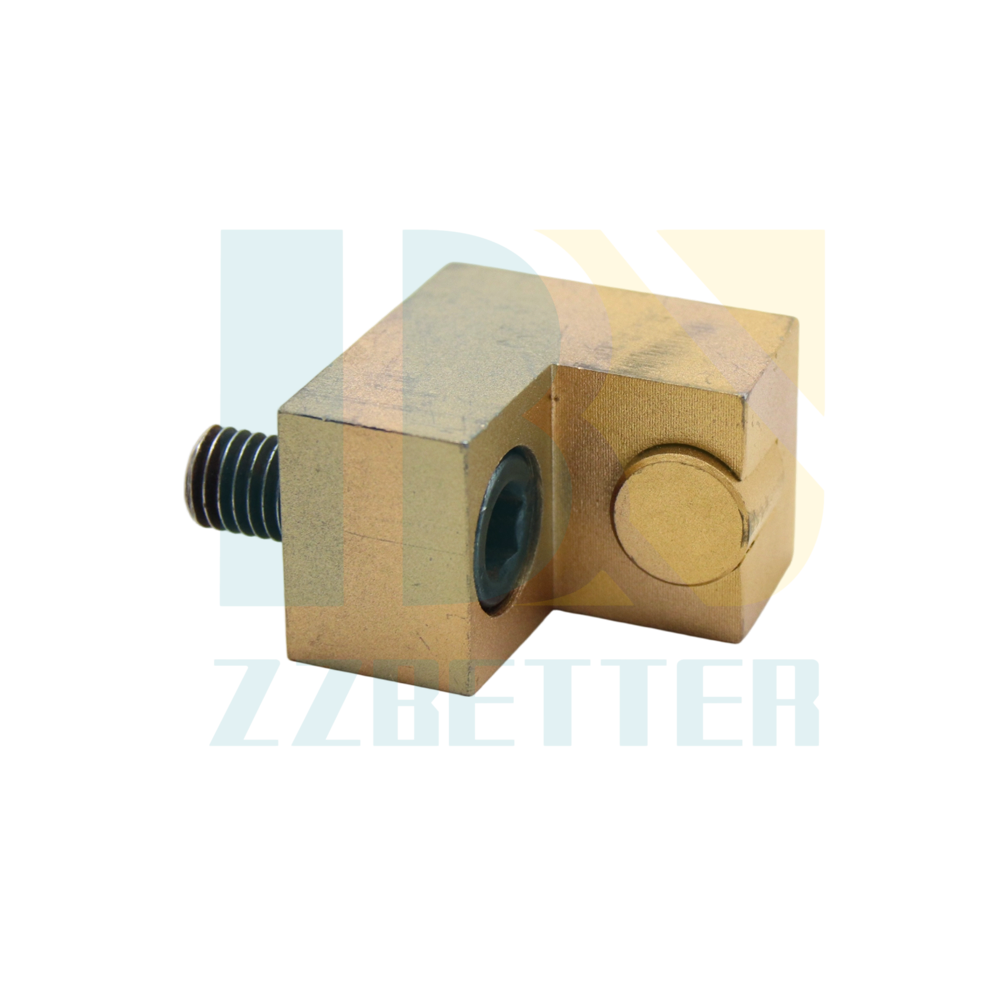

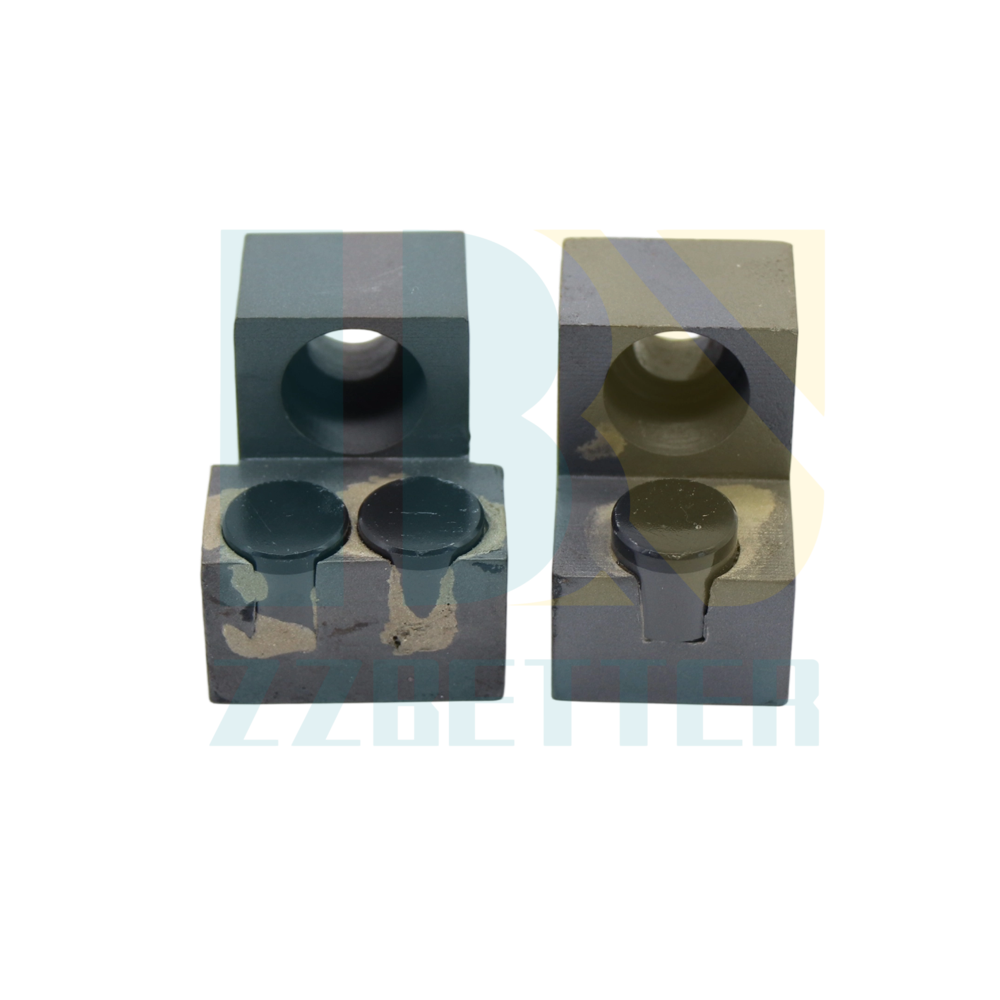

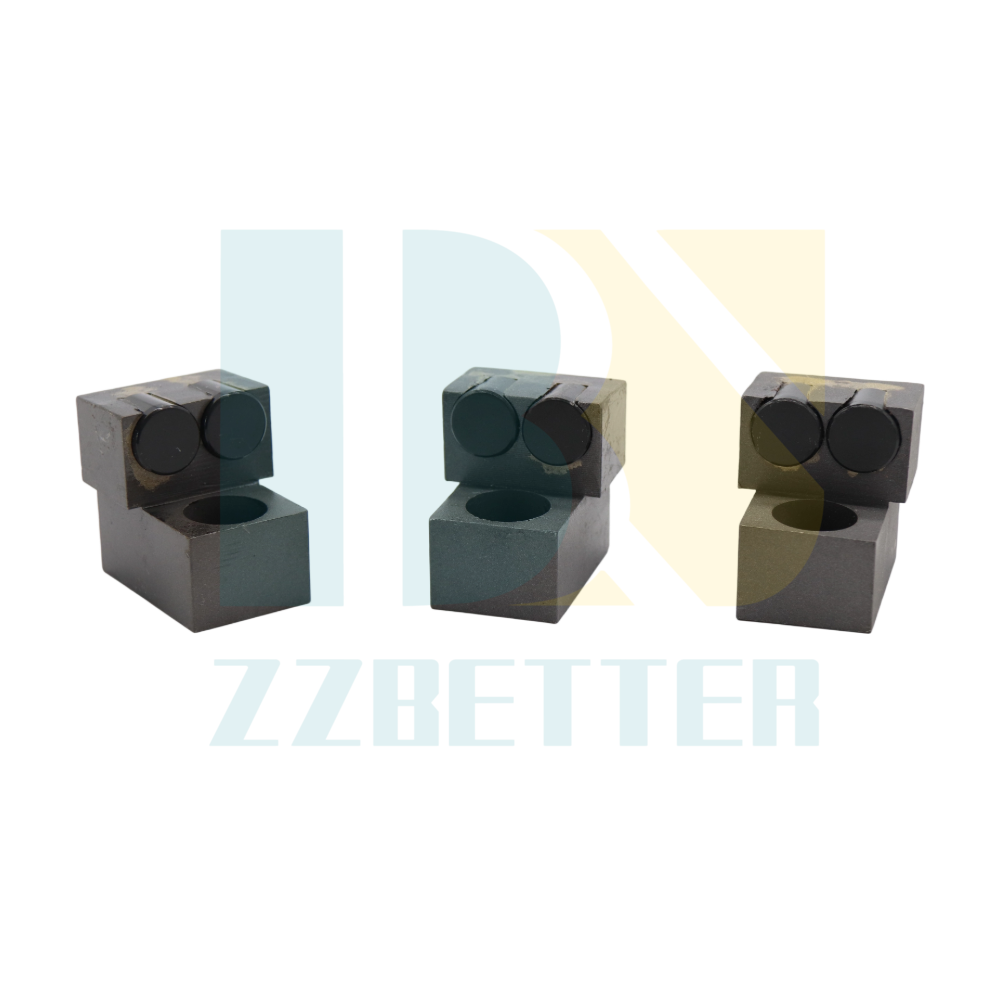

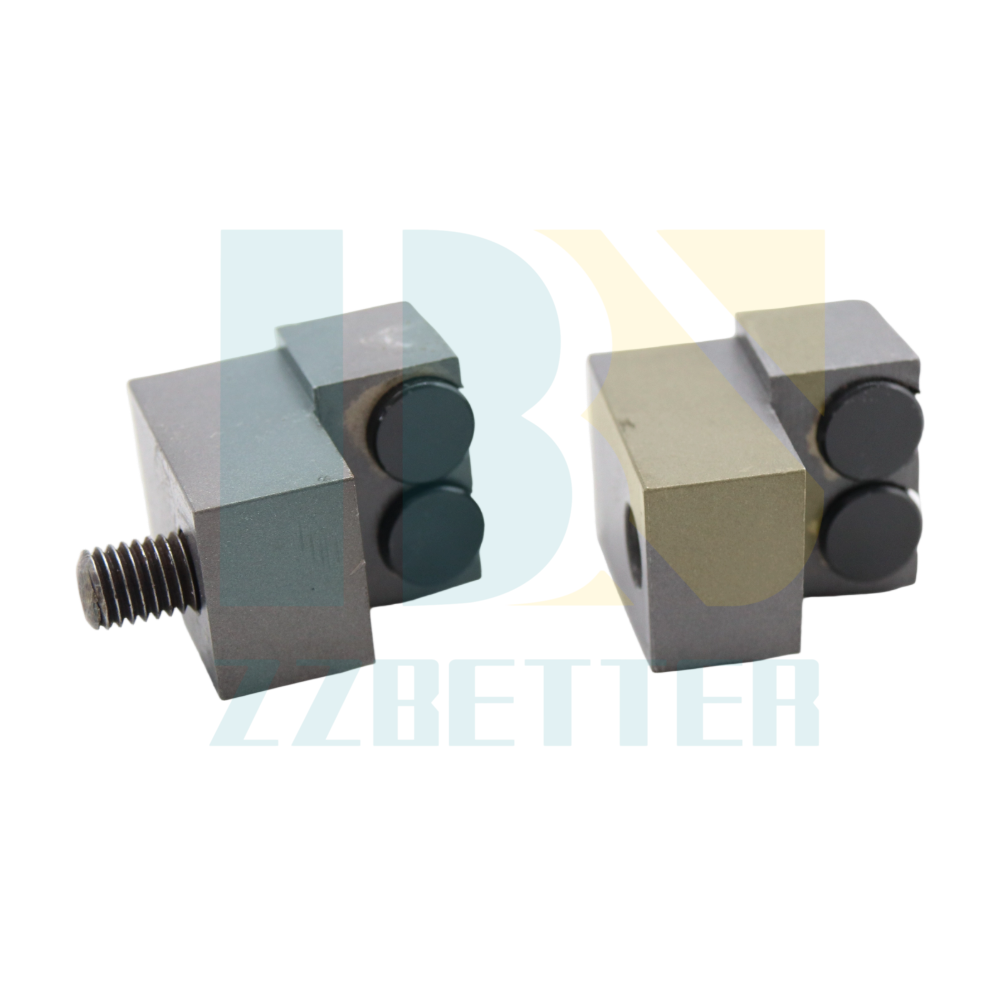

PDC cutters for road milling

Road milling or pavement milling (cold planing, asphalt milling, or profiling) is the process of removing at least part of the surface of a paved area such as a road, bridge, or parking lot. Milling removes anywhere from just enough thickness to level and smooth the surface to a full depth removal. There are some different reasons for milling a paved area instead of simply repaving over the existing surface. Recycling of the road surface is one of the main reasons for milling a road surface.

The PDC cutter is used in place of conventional tungsten carbide picks in the new PDC road milling. These PDC cutter tips provide the hardness and abrasion resistance of diamonds with the toughness of tungsten carbide. The use of PDC technology in PDC road picks greatly reduces pick wear, providing longer service life and greatly reducing downtime to change picks.

▷▶Asphalt Pavement Milling: Precisely remove worn asphalt surfaces for road rehabilitation while maintaining specified grades and slopes.

▷▶Concrete Surface Texturing: Create controlled grooves and textures on concrete pavements to enhance skid resistance and vehicle safety.

▷▶Road Marking Removal: Efficiently eliminate existing road markings with minimal damage to the underlying pavement structure.

▷▶Bridge Deck Scarflying: Remove deteriorated concrete and prepare surfaces on bridge decks for effective overlay and waterproofing repairs.

▷▶Parking Lot Leveling: Correct rutting and irregularities in parking areas to restore proper drainage and smooth vehicle movement.

Features of PDC Cutters for Road Milling:

▷▶High-Efficiency Cutting & Superior Speed: The PCD Tools will be extremely destructive to the ground, smashing the ground and digging out the gravel, the speed is greatly improved than drilling by grinding;

▷▶Exceptional Wear Resistance & Sustained Sharpness: Improve the wear resistance and maintain the sharpness by using PCD as the tip;

▷▶Outstanding Longevity & Cost-Effectiveness: The service life of a PDC cutter is about 30 times of the tungsten carbide cutter when used for milling asphalt concrete. The milling efficiency is about 20% higher than tungsten carbide cutters.

Unmatched Efficiency

·Achieve 20%+ faster milling speeds than conventional carbide tools

·Advanced shearing action removes material more efficiently than grinding

·Consistent performance maintains project timelines

Exceptional Longevity

·Lasts 30x longer than standard tungsten carbide tools

·PCD tips maintain cutting sharpness throughout product life

·Reduced tool change frequency maximizes operational uptime

Superior Cost Performance

·Lower cost-per-square-meter despite higher initial investment

·Fewer replacements reduce maintenance costs and downtime

·Optimal balance of performance and durability for maximum ROI

Proven Reliability

·Engineered for toughest asphalt and concrete conditions

·Rigorous quality control ensures every tool meets specifications

·Trusted by major construction companies worldwide

Technical Excellence

·Optimized tool geometry for efficient material removal

·Specialized PCD formulations for enhanced wear resistance

·Continuous R&D driving industry standards forwar

ZZBetter: Your Leading PDC cutters Manufacturer & Supplier

-----------------------------------------------------------------------------------------------------------------------------

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China, 412000

Tel:0086 73128705418

Phone:0086 13647338188

Fax:0086 073128510897

Email:PDC@drillbetter.com

Whatsapp: 008618173362360