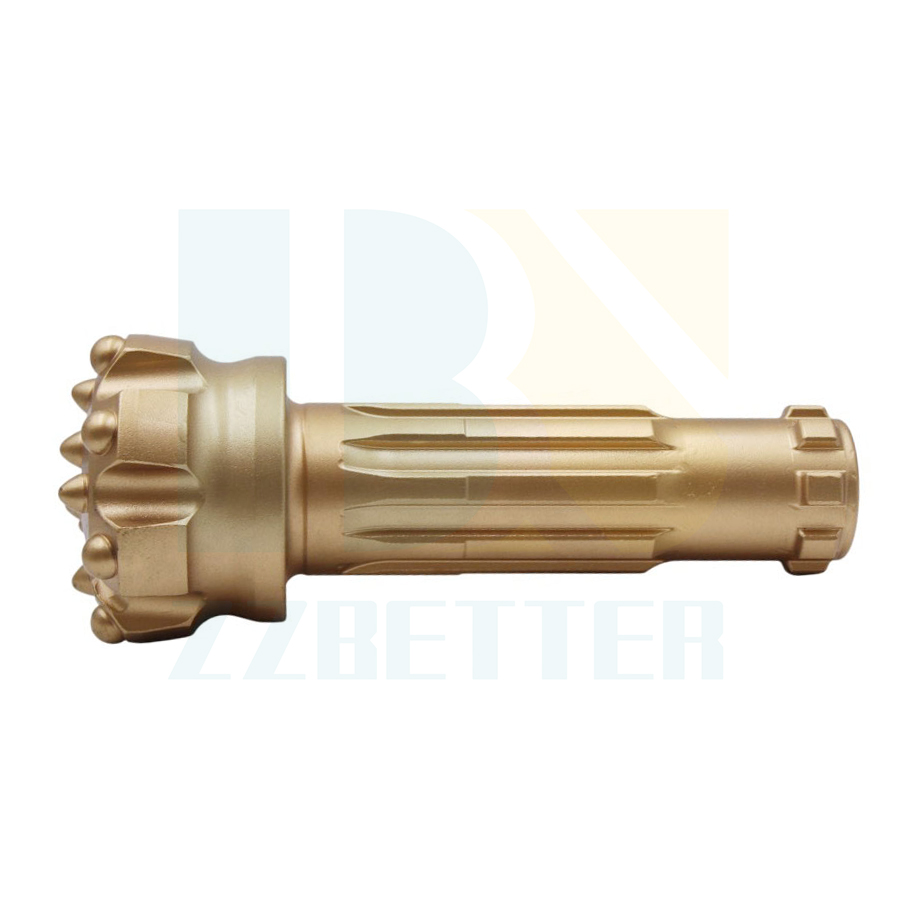

PDC DTH Bit

Cutter Type: PDC

Center/Primary Cutter Size: 13 mm, 16 mm, 19 mm

Suitable Formation: Medium Hard - Extremely Hard Formations (Granite, Basalt, Hard Limestone)

Customization Supported: Yes (OEM Accepted)

Request a quote for detailed information (MOQ, price, delivery)

PDC DTH Bit :

From standard cutters to custom drilling solutions, we provide the industry's most reliable PDC products for extreme conditions.

Revolutionizing Down-The-Hole Drilling

Our PDC DTH Hammer Bit represents a groundbreaking advancement in percussive drilling technology. By integrating premium Polycrystalline Diamond Compact (PDC) cutters with robust hammer bit design, we have created a tool that delivers unparalleled drilling efficiency in hard rock formations. Unlike conventional hammer bits that rely solely on crushing action, our PDC DTH Bit combines the impact energy of down-the-hole hammer with the superior shearing capability of PDC cutters, resulting in up to 60% faster penetration rates and significantly reduced drilling costs.

Engineered for Extreme Conditions

Each PDC DTH Bit features strategically placed, high-grade PDC cutters that are specifically selected for their exceptional impact and abrasion resistance. The cutters are mounted on a precision-machined bit body made from premium alloy steel, heat-treated for maximum toughness and fatigue resistance. Advanced computational modeling optimizes both the cutter placement for efficient rock removal and the fluid passage design for effective cuttings evacuation and bit cooling, ensuring sustained performance in the most demanding drilling conditions.

By fusing the percussive power of Down-The-Hole hammers with the cutting superiority of PDC cutters, we deliver a solution that outperforms conventional hammer bits in abrasive and hard rock formations.

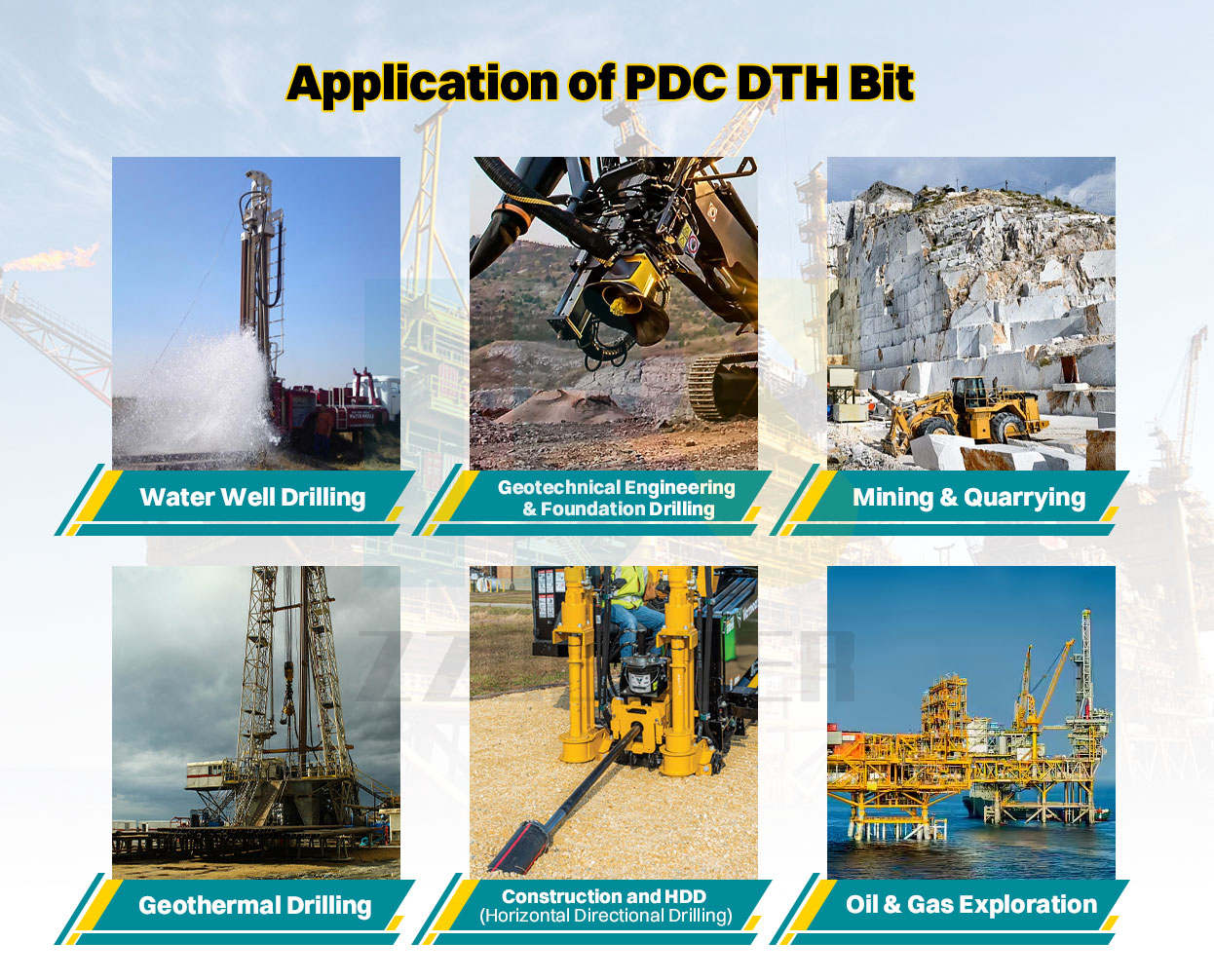

▷▶Water Well Drilling: Efficiently drill large-diameter water wells in hard rock and sandstones.

▷▶Geotechnical Engineering & Foundation Drilling: Perfect for soil sampling, anchor drilling, and micropile construction in mixed and hard ground conditions.

▷▶Mining & Quarrying: Blast hole drilling, exploration drilling, and production drilling in mineral mines and quarries.

▷▶Geothermal Drilling: Handle the hard, crystalline rocks typically encountered in geothermal energy projects.

▷▶Construction and HDD (Horizontal Directional Drilling): Used for piling, foundation support, and larger-scale HDD projects requiring durability and speed.

▷▶Oil & Gas Exploration: (Seismic drilling, coring) Suitable for top-hole drilling and certain exploration applications.

▷▶Exceptional Rate of Penetration (ROP): The sharp, thermally stable PDC cutters shear through rock with ease, significantly increasing your meters drilled per hour and reducing overall project time.

▷▶Superior Abrasion Resistance: The synthetic diamond table of each PDC cutter offers extreme hardness, providing outstanding wear resistance in sandy, abrasive formations where conventional bits fail quickly.

▷▶Enhanced Durability & Long Service Life: Manufactured from high-grade alloy steel and featuring advanced brazing technology, our bits are built to withstand intense impact and fatigue, ensuring a longer operational life and lower cost-per-meter.

▷▶Excellent Stability and Straight-Hole Drilling: The optimized blade and gauge design provides superior directional stability, reducing deviation and ensuring accurate, straight holes.

▷▶Reduced Operating Costs: Fewer bit trips mean less downtime, lower fuel consumption, and reduced labor costs, leading to a significantly higher return on investment (ROI).

Get a competitive quote today!

Your Trusted Partner for Drilling Success

We are a professional manufacturer with a focus on quality and innovation. Every PDC button bit undergoes rigorous quality control to ensure it meets the highest standards before shipment. We offer OEM services and custom engineering to meet your unique project requirements.

Unmatched Performance

·Achieve 40-60% faster penetration rates in hard rock

·Extend bit life by 50% compared to conventional hammer bits

·Maintain consistent performance in abrasive formations

Advanced Technology

·Patented PDC cutter layout for optimal impact energy transfer

·Proprietary steel treatment process for enhanced durability

·Innovative flushing system prevents bit balling

Proven Reliability

·Field-tested in over 800 drilling projects worldwide

·Withstand extreme impact loads up to 25 joules

·Maintain structural integrity in deepest drilling applications

Cost Efficiency

·Reduce total drilling cost by 30-45%

·Minimize downtime with extended service intervals

·Lower maintenance requirements through robust design

Expert Support

·24/7 technical consultation from drilling experts

·Fast replacement service with global logistics network

·Custom engineering solutions for specific projects

ZZBetter: Your Leading PDC cutters Manufacturer & Supplier

-----------------------------------------------------------------------------------------------------------------------------

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China, 412000

Tel:0086 73128705418

Phone:0086 13647338188

Fax:0086 073128510897

Email:PDC@drillbetter.com

Whatsapp: 008618173362360