PDC Drag Bit

Cutter Type: PDC

Cutter Size: 13 mm, 16 mm, 19 mm

Suitable Formation: Soft - Medium Hard Formations(Mudstone, Shale, Sandstone, Limestone)

Customization Supported: Yes (OEM Accepted)

Request a quote for detailed information (MOQ, price, delivery)

PDC Drag Bit :

From standard cutters to custom drilling solutions, we provide the industry's most reliable PDC products for extreme conditions.

The PDC Drag Bit represents the pinnacle of fixed-cutter drilling technology, engineered to deliver unmatched rates of penetration (ROP) and superior drilling efficiency in a wide range of formations. Unlike roller cone bits that crush rock through a rolling action, the drag bit utilizes the continuous shearing force of strategically placed Polycrystalline Diamond Compact (PDC) cutters to slice through rock with exceptional speed and smoothness. This advanced bit design is the preferred choice for applications where speed, stability, and consistent performance are critical to reducing overall drilling time and cost.

PDC drag bits are versatile and widely used in several industries:

▶▷Water Well Drilling: Ideal for fast drilling of boreholes in clay, shale, and soft sandstone formations.

▶▷Geotechnical Investigation: Used for sonic drilling, soil sampling, and other exploration where fast penetration is needed.

▶▷Construction Drilling: Efficient for drilling for anchor bolts, soil nails, and micropiles.

▶▷Oil & Gas (Surface Sections): Excellent for top-hole sections where soft formations are encountered.

Mining & Blast Hole Drilling: Used in suitable soft rock strata for rapid drill-through.

▶▷Extremely High ROP: The shearing action provides the fastest drilling speeds available for compatible formations.

▶▷Smooth, Vibration-Free Operation: Provides a stable drilling process, reducing stress on the drill string and rig.

▶▷Excellent Borehole Quality: Produces a clean, precise, and in-gauge borehole.

▶▷Durability in Target Formations: Offers significantly longer life than tri-cone or carbide bits in soft formations.

▶▷Simple and Robust Design: No moving parts, which minimizes the risk of mechanical failure.

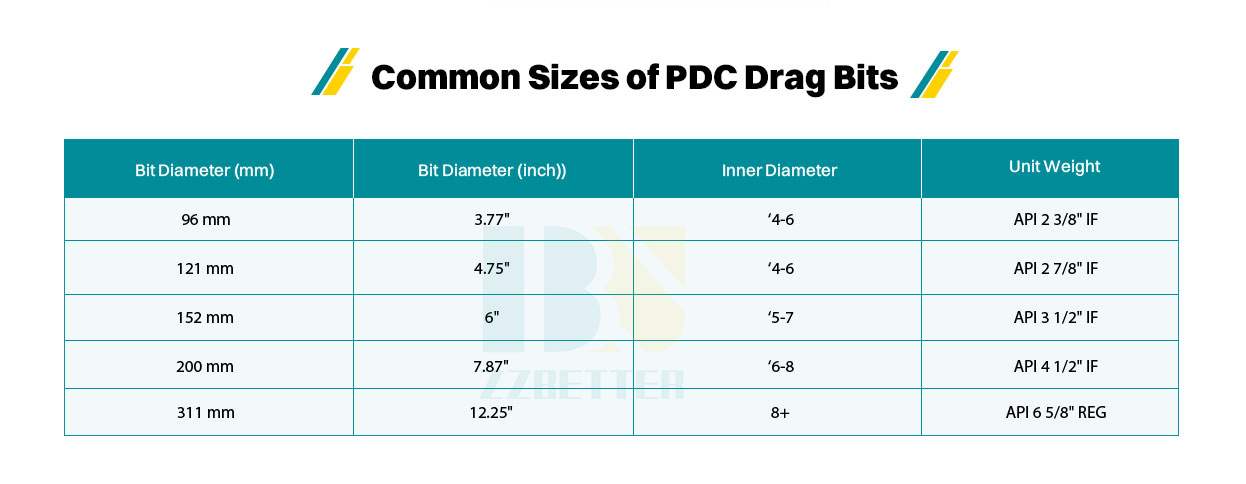

Custom sizes and connections are available as OEM orders.

Proven Performance Excellence

·Documented 35-50% faster ROP than conventional bits

·Achieve 30% longer service life through optimized cutter technology

·Maintain consistent performance across formation transitions

Advanced Engineering Design

·Patented asymmetric blade layout for superior stability

·Precision-engineered fluid dynamics for optimal cutter cleaning

·Customizable cutter configuration for specific formation challenges

Unmatched Reliability

·98% on-time delivery performance

·Rigorous quality control with individual bit tracking

·Field-proven in over 1,200 drilling projects worldwide

Technical Innovation

·Advanced depth-of-control technology prevents stick-slip

·Proprietary PDC grades for enhanced wear resistance

·Balanced cutting structure reduces vibration damage

Global Support Network

·24/7 technical advisory service

·Rapid response spare parts program

·On-site engineering support available

ZZBetter: Your Leading PDC cutters Manufacturer & Supplier

-----------------------------------------------------------------------------------------------------------------------------

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China, 412000

Tel:0086 73128705418

Phone:0086 13647338188

Fax:0086 073128510897

Email:PDC@drillbetter.com

Whatsapp: 008618173362360