PDC Pick

Cutter Type: PDC

PDC Cutter Size: 13 mm, 16 mm, 19 mm

Compatible Machine: Roadheader, Shearers, Coal Miner, Milling Machine

Customization Supported: Yes (OEM Accepted)

Request a quote for detailed information (MOQ, price, delivery)

PDC Pick :

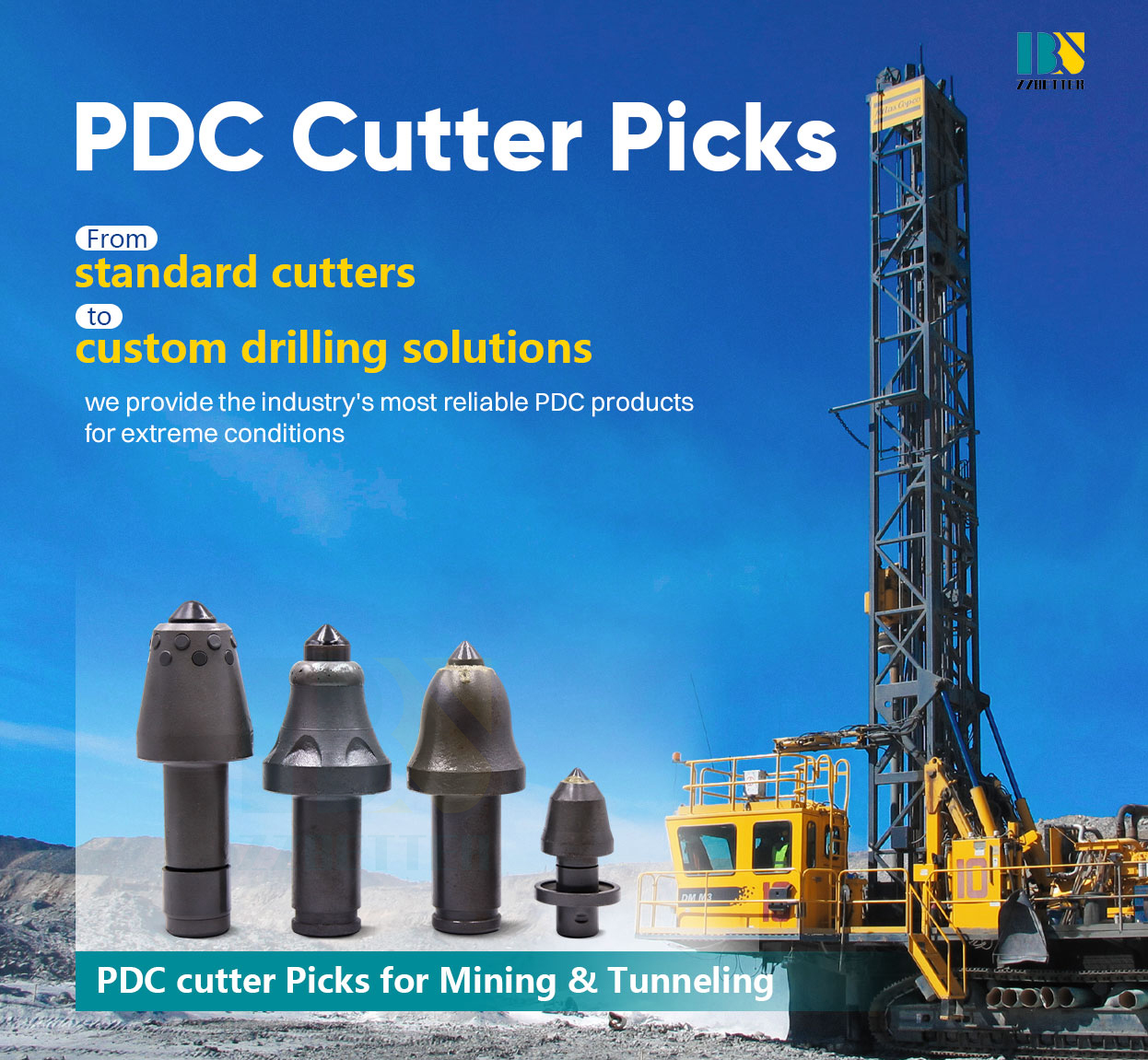

From standard cutters to custom drilling solutions, we provide the industry's most reliable PDC products for extreme conditions.

Next-Generation Cutting Solution for Modern Excavation

Our PDC Pick represents a revolutionary advancement in cutting technology, engineered to deliver exceptional performance in the most demanding mining and tunneling applications. By integrating premium polycrystalline diamond compact (PDC) cutters with an optimized pick body design, we have created a cutting tool that outperforms conventional picks in both efficiency and durability. The unique combination of extreme hardness and exceptional wear resistance makes our PDC Pick the ideal choice for abrasive formations and continuous mining operations.

Advanced Engineering for Superior Performance

Each PDC Pick features a strategically positioned PDC cutter that is precisely brazed to a high-strength tungsten carbide body. This advanced configuration ensures maximum cutting efficiency while maintaining exceptional impact resistance. The pick's geometry is optimized through computational analysis to reduce cutting forces and improve rock fragmentation, resulting in lower energy consumption and reduced tool wear. Special attention is paid to the pick's body design, which provides superior mechanical strength and reliable mounting stability in various tool holders.

Enhanced Durability Design

The PDC Pick is manufactured using premium materials and state-of-the-art production processes. The PDC cutter features our proprietary diamond table formulation that provides unmatched abrasion resistance, while the specially designed carbide substrate offers excellent impact strength. The optimized interface between the PDC element and pick body ensures maximum structural integrity, preventing premature failure even under extreme cyclic loading conditions.

Our PDC miner picks are engineered for heavy-duty applications in extreme conditions:

▷▶Continuous Mining: Ideal for continuous miners and shearers in coal mining and potash mining, especially in abrasive seams.

▷▶Tunnel Boring & Roadheading: Perfect for tunnel boring machines (TBMs) and roadheaders driving through sandy, abrasive rock and mixed ground conditions.

▷▶Trenching and Horizontal Directional Drilling (HDD): Protect your trencher chains and HDD reamer tools in rocky, sandy soils.

▷▶Surface Mining and excavation: Used on surface miners and drum cutters for precise and efficient excavation of hard, abrasive rock.

▷▶Construction and Foundation Work: Excellent for milling and cutting in reinforced concrete and abrasive construction materials.

▷▶Longer Service Life: The PDC diamond table provides unparalleled wear resistance, outlasting even the best-grade tungsten carbide picks by a massive margin.

▷▶Maintained Cutting Speed: The sharp, diamond-edge shears through material consistently, preventing the drop in penetration rate seen with worn carbide picks.

▷▶Reduced Machine Stress: A sharper pick requires less force to cut, decreasing vibration and stress on your roadheader, continuous miner, or trenching machine components.

▷▶Significantly Lower Operating Costs: Drastically reduce the costs associated with frequent pick replacement: parts inventory, labor downtime, and machine stoppage.

▷▶Robust Construction: Forged from high-quality alloy steel and using a superior vacuum brazing process to secure the PDC cutter, ensuring impact resistance and reliability.

We specialize in manufacturing high-quality replacement PDC picks for major OEM brands and custom designs.We offer full OEM compatibility and custom engineering. Please provide your machine model or a sample of your current pick for a perfect match.

Proven Performance Benefits

·70% longer service life compared to conventional carbide picks

·40% reduction in cutting force requirements

·Maintain sharp cutting edge throughout tool life

·Consistent performance in abrasive formations

Technical Superiority

·Proprietary PDC formulation for enhanced wear resistance

·Optimized pick geometry for efficient rock fragmentation

·Advanced brazing technology ensures superior bond strength

·Custom designs available for specific applications

Economic Advantages

·Reduce tool replacement frequency by 60%

·Lower overall operating costs through extended service life

·Decrease energy consumption with optimized cutting geometry

·Minimize downtime for tool changes

Reliability Assurance

·Rigorous quality control at every manufacturing stage

·Field-tested in over 300 mining and tunneling projects

·Consistent performance across varying geological conditions

·Robust construction withstands extreme impact loads

Professional Support

·Technical consultation for application optimization

·Custom engineering solutions for unique challenges

·Global logistics support for timely delivery

·Comprehensive after-sales service network

Every PDC pick is manufactured under strict quality control protocols. We use only premium-grade PDC cutters and high-tensile steel to ensure you get a product that performs as promised.

Stop replacing picks—start dominating your dig site. Contact us today with your machine model for a quote and see how much you can save.

ZZBetter: Your Leading PDC cutters Manufacturer & Supplier

-----------------------------------------------------------------------------------------------------------------------------

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China, 412000

Tel:0086 73128705418

Phone:0086 13647338188

Fax:0086 073128510897

Email:PDC@drillbetter.com

Whatsapp: 008618173362360