PDC Spherical Cutter

Shape: Spherical

Application: PDC drill bit, DTH drill bit, Diamond pick, Anchor bit, Core bit

Advantages: Enhanced wear resistance, impact resistance, Superior formation adaptability

Request a quote for detailed information (MOQ, price, delivery)

PDC Spherical Cutter :

From standard cutters to custom drilling solutions, we provide the industry's most reliable PDC products for extreme conditions.

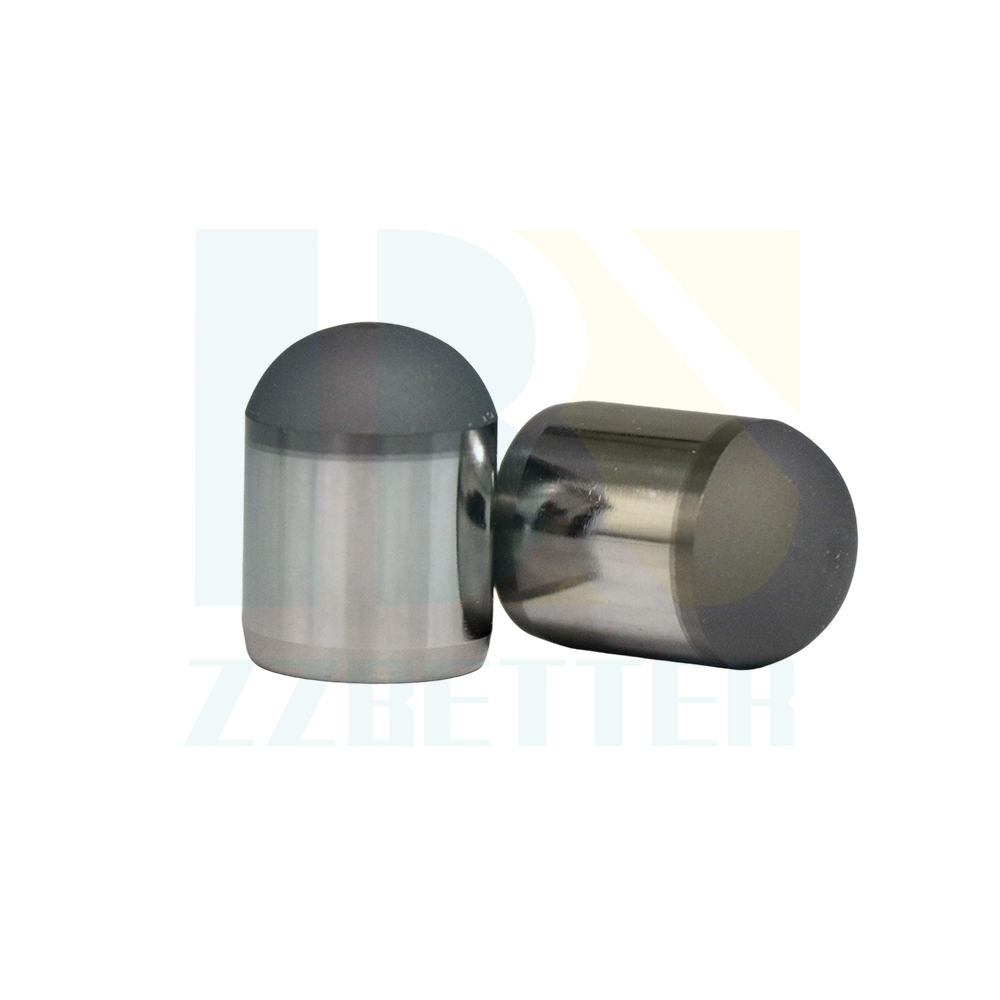

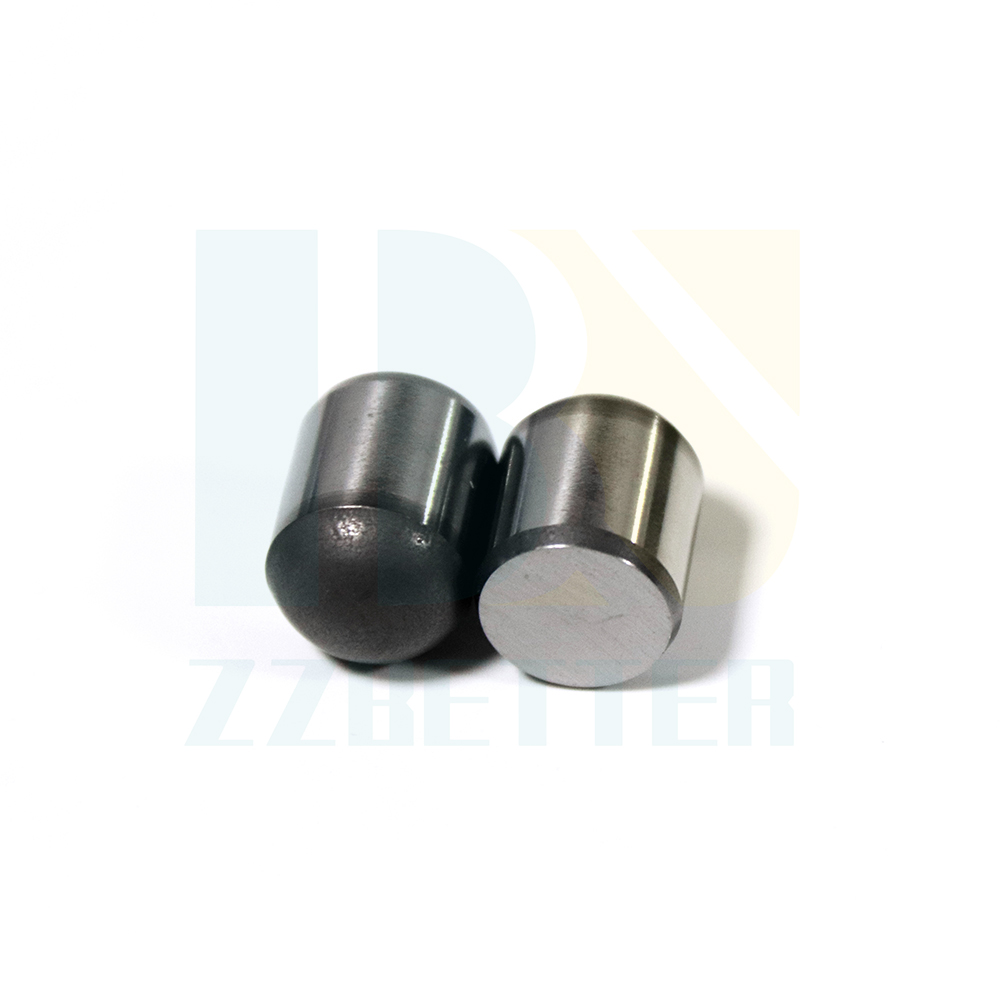

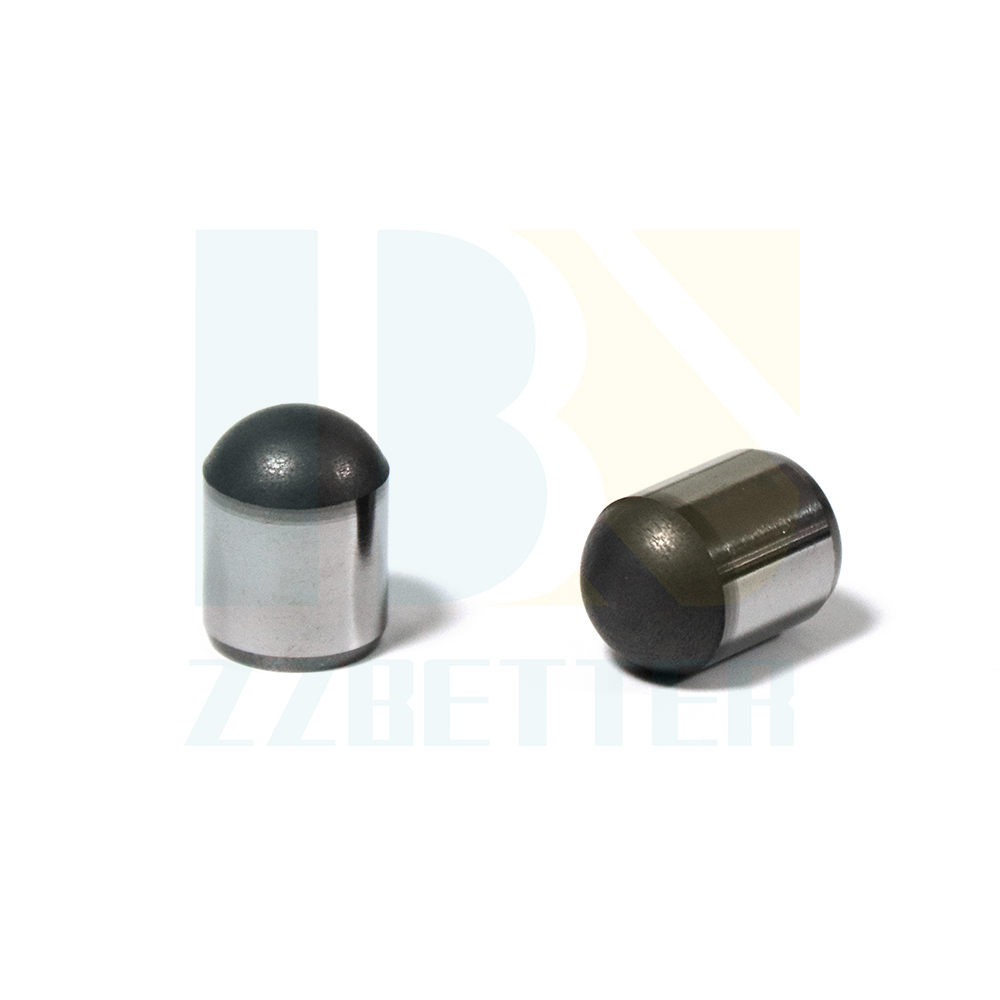

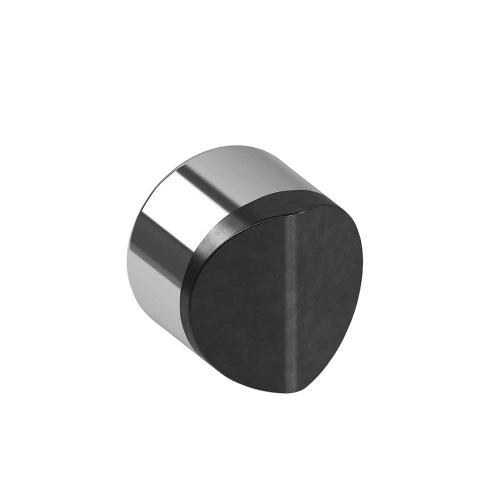

PDC Spherical Cutters, also known as Ballistic Cutters, feature a revolutionary hemispherical geometry that sets them apart from traditional flat cutters. This dome-shaped design is specifically engineered to excel in the most challenging drilling environments where impact resistance is paramount. The spherical shape inherently distributes external forces evenly in all directions, effectively minimizing stress concentration at any single point. This fundamental design principle allows spherical cutters to withstand severe impact loading and resist catastrophic failure when encountering hard stringers, interbedded formations, or other downhole obstacles. Manufactured using the same high-temperature, high-pressure (HPHT) sintering process that bonds a premium polycrystalline diamond table to a tungsten carbide substrate, these cutters deliver exceptional durability without compromising on the intrinsic wear resistance and thermal stability characteristic of premium PDC materials.

PDC Spherical Cutters, also known as Ballistic Cutters, feature a revolutionary hemispherical geometry that sets them apart from traditional flat cutters. This dome-shaped design is specifically engineered to excel in the most challenging drilling environments where impact resistance is paramount. The spherical shape inherently distributes external forces evenly in all directions, effectively minimizing stress concentration at any single point. This fundamental design principle allows spherical cutters to withstand severe impact loading and resist catastrophic failure when encountering hard stringers, interbedded formations, or other downhole obstacles. Manufactured using the same high-temperature, high-pressure (HPHT) sintering process that bonds a premium polycrystalline diamond table to a tungsten carbide substrate, these cutters deliver exceptional durability without compromising on the intrinsic wear resistance and thermal stability characteristic of premium PDC materials.

Unlike flat cutters that primarily utilize a shearing action, the working principle of the PDC Spherical Cutter is a combination of impact, crushing, and localized shearing. The rounded point contacts the rock formation with extremely high point-loading, effectively fracturing the rock through compressive strength. As the bit rotates, the spherical surface rolls and slides against the formation, continuously applying this concentrated stress to crush and break the rock ahead of it. This mechanism is exceptionally effective in brittle and hard formations where shear strength is high. The ability to absorb and redistribute impact energy makes the spherical cutter not just a cutting tool, but a robust, shock-absorbing component that protects the entire drill bit structure.

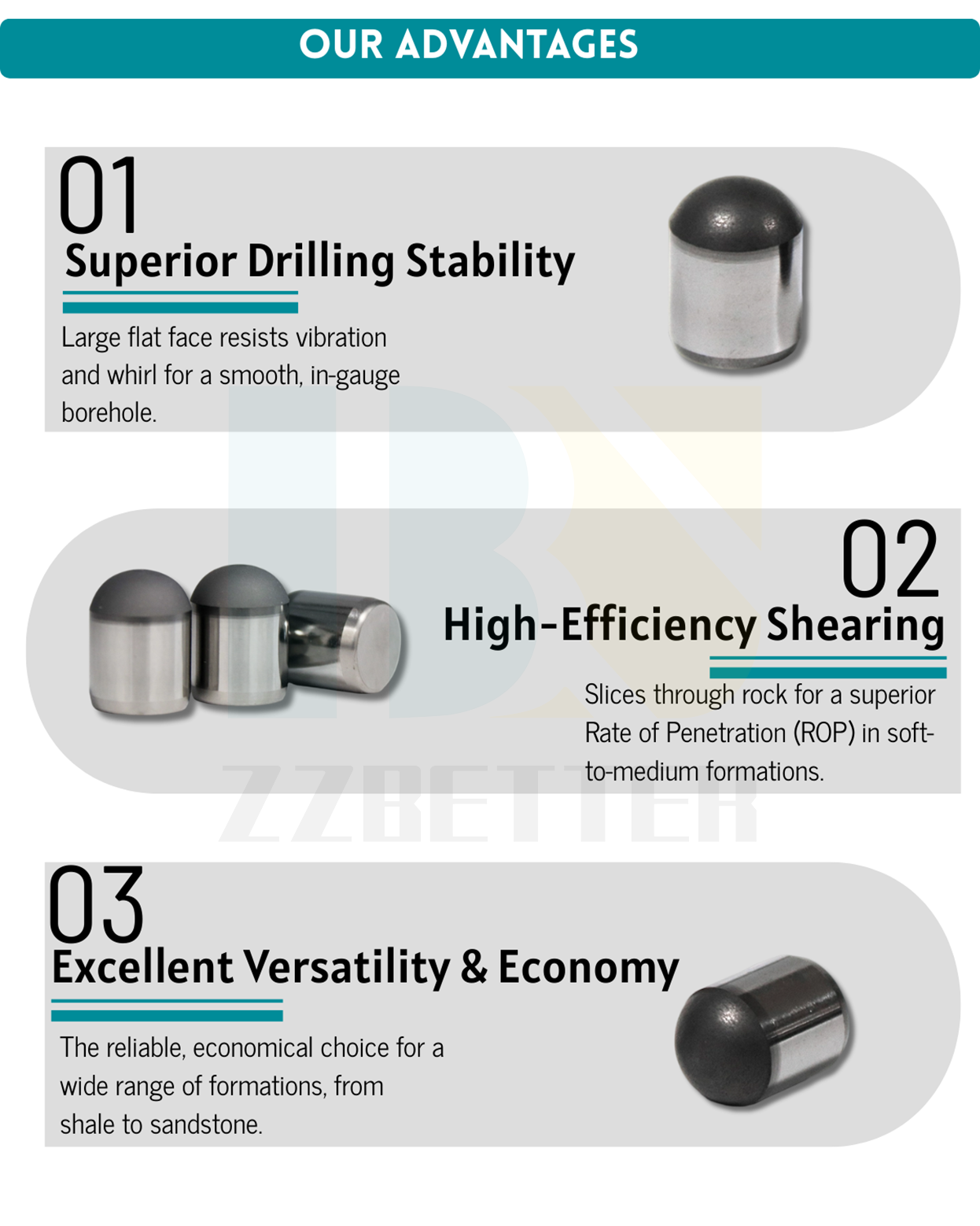

The defining feature of PDC Spherical Cutters is their unmatched impact resistance, making them the superior choice for drilling through hard, abrasive, and interbedded formations. Their key advantages include Enhanced Durability, as the hemispherical design provides a larger volume of diamond material behind the cutting point, significantly increasing its resistance to abrasive wear and extending service life. Furthermore, they offer Superior Stability by helping to suppress destructive bit whirl and vibration, leading to smoother drilling operation and improved borehole quality. This geometry also provides Exceptional Versatility in Hard Formations, reliably performing in conditions that would typically cause rapid failure in flat cutters, such as when drilling through sandstone, chert, and shale sequences.

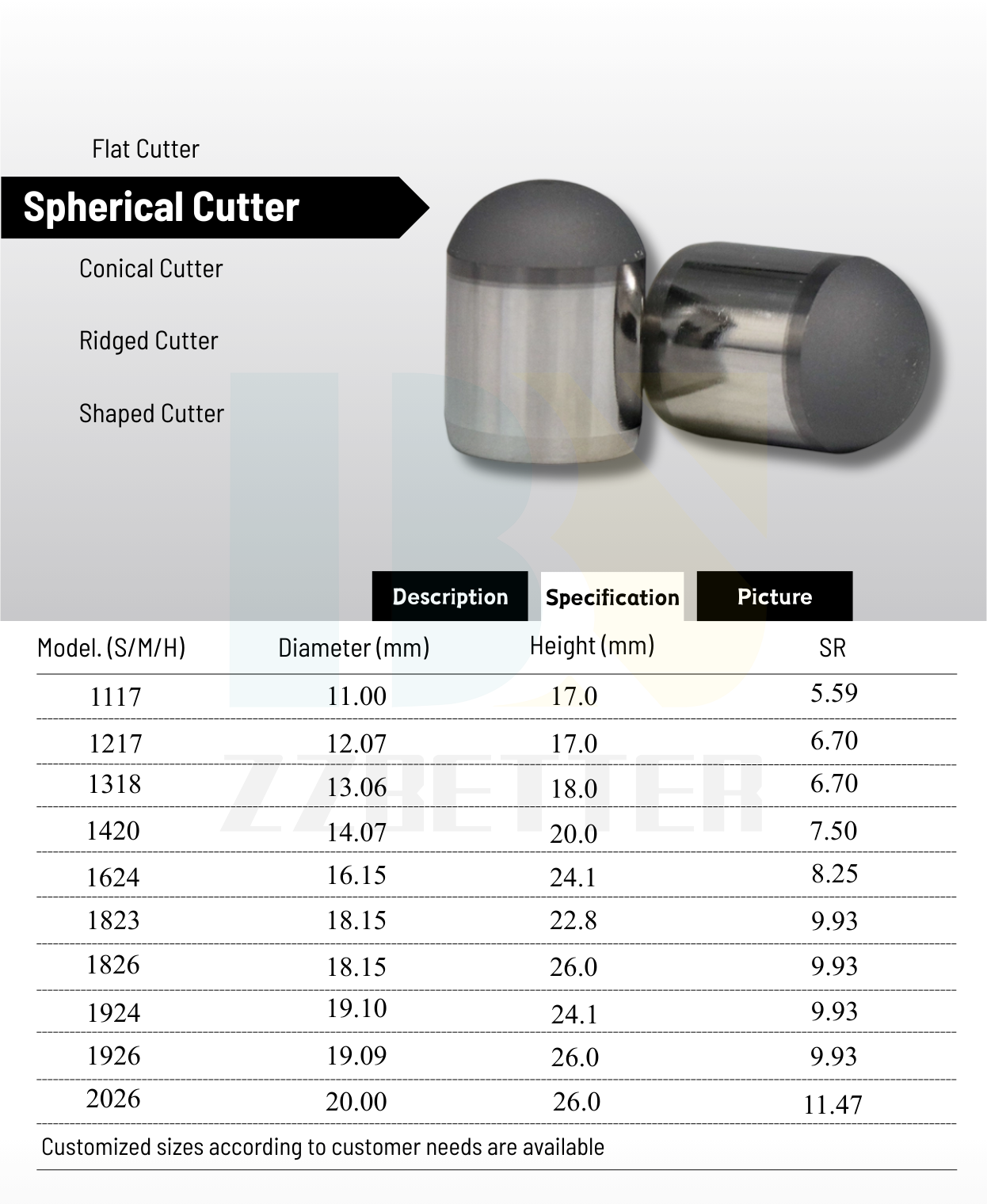

ZZBETTER Spherical Cutters are available in a range of standard diameters to suit various bit designs and operational requirements. They are predominantly used as secondary or backup cutters on PDC bits destined for geologically complex intervals. Their primary application is in Hard Rock Drilling for oil and gas, mining, and geothermal projects, especially in formations containing chert, pyrite, or quartzite. They are also critical components in Directional Drilling applications where toolface control is essential, as their stability contributes to consistent steerability. Furthermore, they are invaluable in Milling and Workover Operations, such as milling out casing shoes or cement, where unpredictable impact loads are common.

Our uniquely designed cutting element geometry enhances cutting efficiency and the durability of PDC bits. This enables our PDC bits to drill at a higher Rate of Penetration (ROP) and achieve greater footage, thereby saving drilling time and costs.

ZZBETTER is excited to help you discover how our high-quality diamond solutions can enhance your work. Don't hesitate to reach out if you have questions or want to learn more about our PDC cutters.

ZZBetter: Your Leading PDC cutters Manufacturer & Supplier

-----------------------------------------------------------------------------------------------------------------------------

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China, 412000

Tel:0086 73128705418

Phone:0086 13647338188

Fax:0086 073128510897

Email:PDC@drillbetter.com

Whatsapp: 008618173362360