PDC Ridged Cutter

Shape: Ridged

Application: PDC drill bit, DTH drill bit, Diamond pick, Anchor bit, Core bit

Advantages: Enhanced wear resistance, impact resistance, Superior formation adaptability

Request a quote for detailed information (MOQ, price, delivery)

PDC Ridged Cutter :

From standard cutters to custom drilling solutions, we provide the industry's most reliable PDC products for extreme conditions.

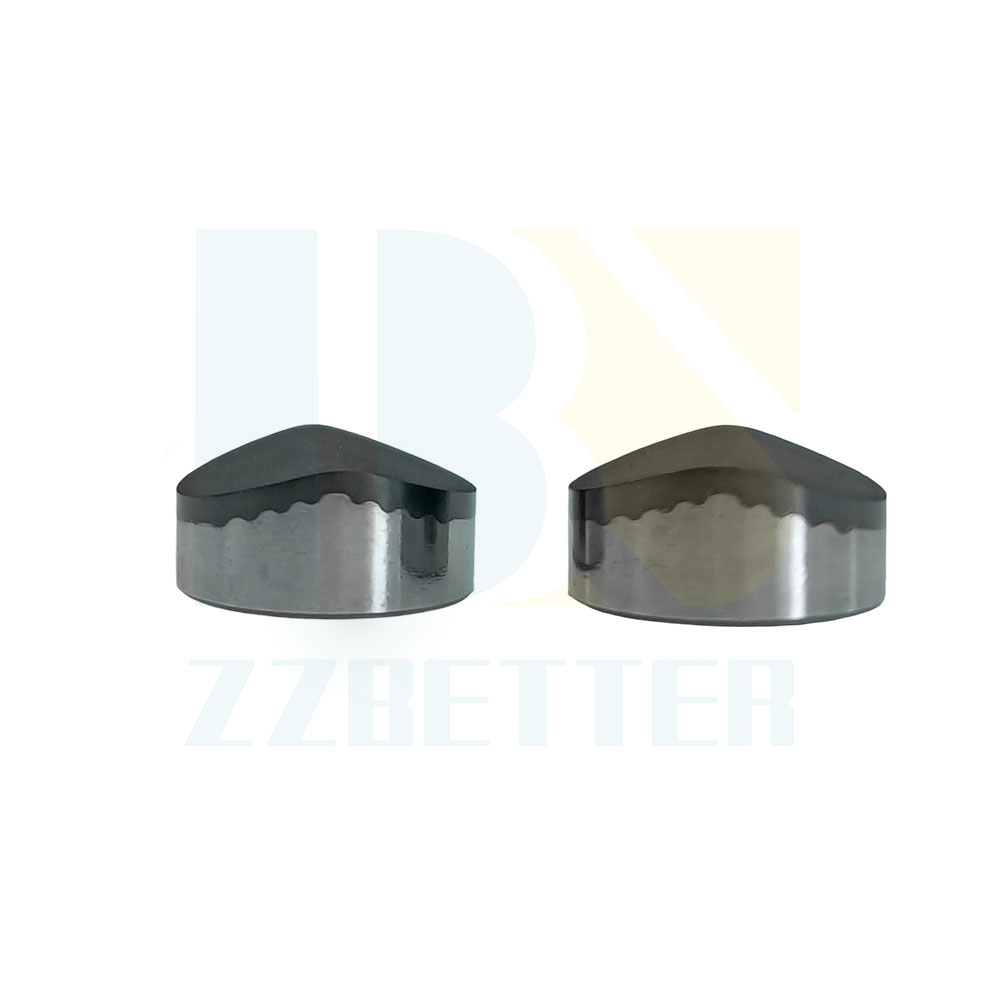

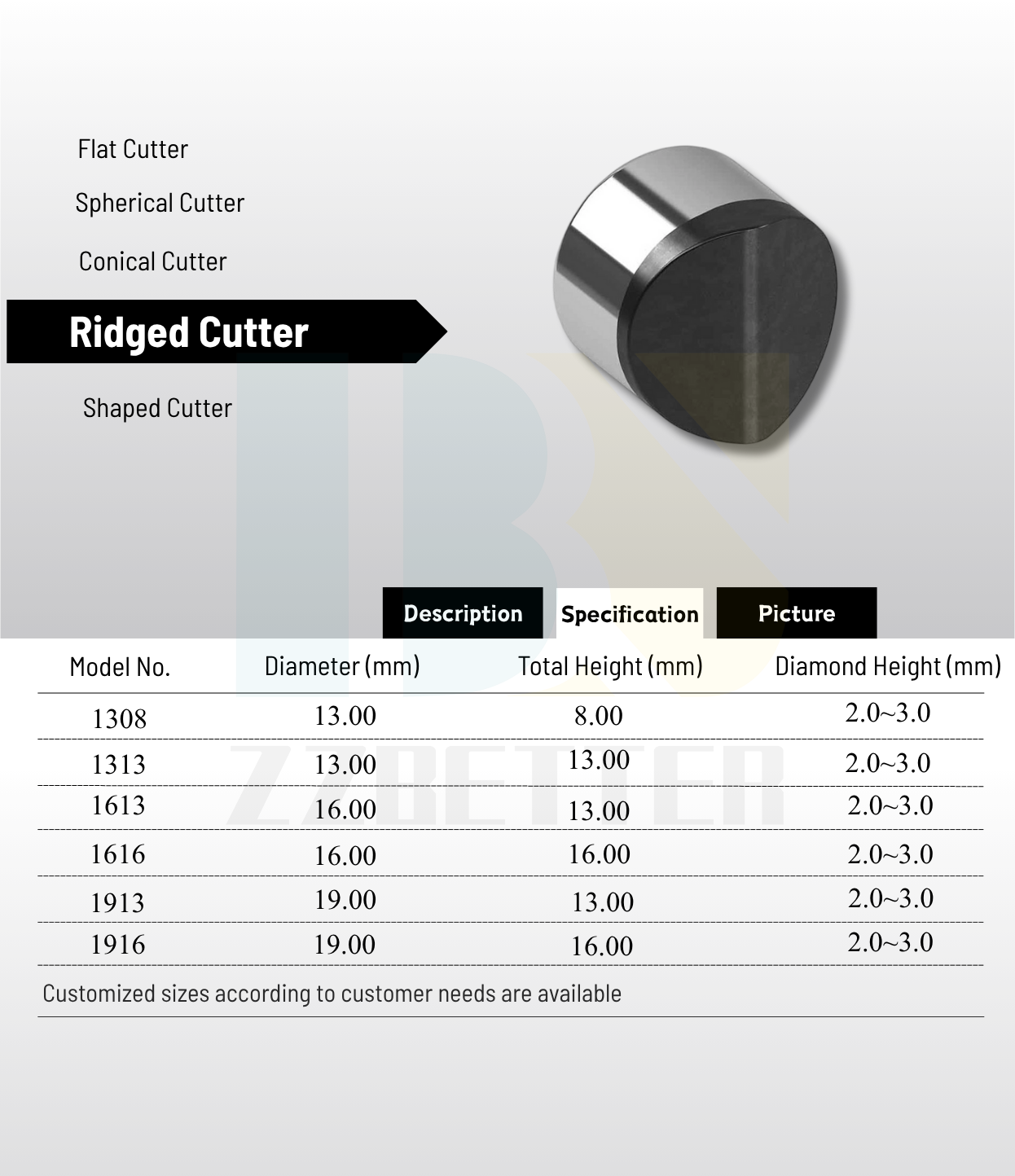

PDC Ridged Cutters feature an innovative non-planar geometry with precisely engineered radial ridges and grooves on the cutting face. This advanced design represents a significant evolution from conventional flat cutters, specifically engineered to address the challenges of both efficient shearing and cuttings removal. The alternating pattern of high points and channels creates multiple focused contact points that dramatically increase localized stress on the rock formation. Simultaneously, the grooves serve as dedicated pathways for cuttings evacuation and coolant flow. Manufactured using the same rigorous HPHT sintering process that bonds a premium polycrystalline diamond table to a tungsten carbide substrate, Ridged Cutters deliver enhanced performance while maintaining the fundamental wear resistance and thermal stability expected from premium PDC materials.

PDC Ridged Cutters feature an innovative non-planar geometry with precisely engineered radial ridges and grooves on the cutting face. This advanced design represents a significant evolution from conventional flat cutters, specifically engineered to address the challenges of both efficient shearing and cuttings removal. The alternating pattern of high points and channels creates multiple focused contact points that dramatically increase localized stress on the rock formation. Simultaneously, the grooves serve as dedicated pathways for cuttings evacuation and coolant flow. Manufactured using the same rigorous HPHT sintering process that bonds a premium polycrystalline diamond table to a tungsten carbide substrate, Ridged Cutters deliver enhanced performance while maintaining the fundamental wear resistance and thermal stability expected from premium PDC materials.

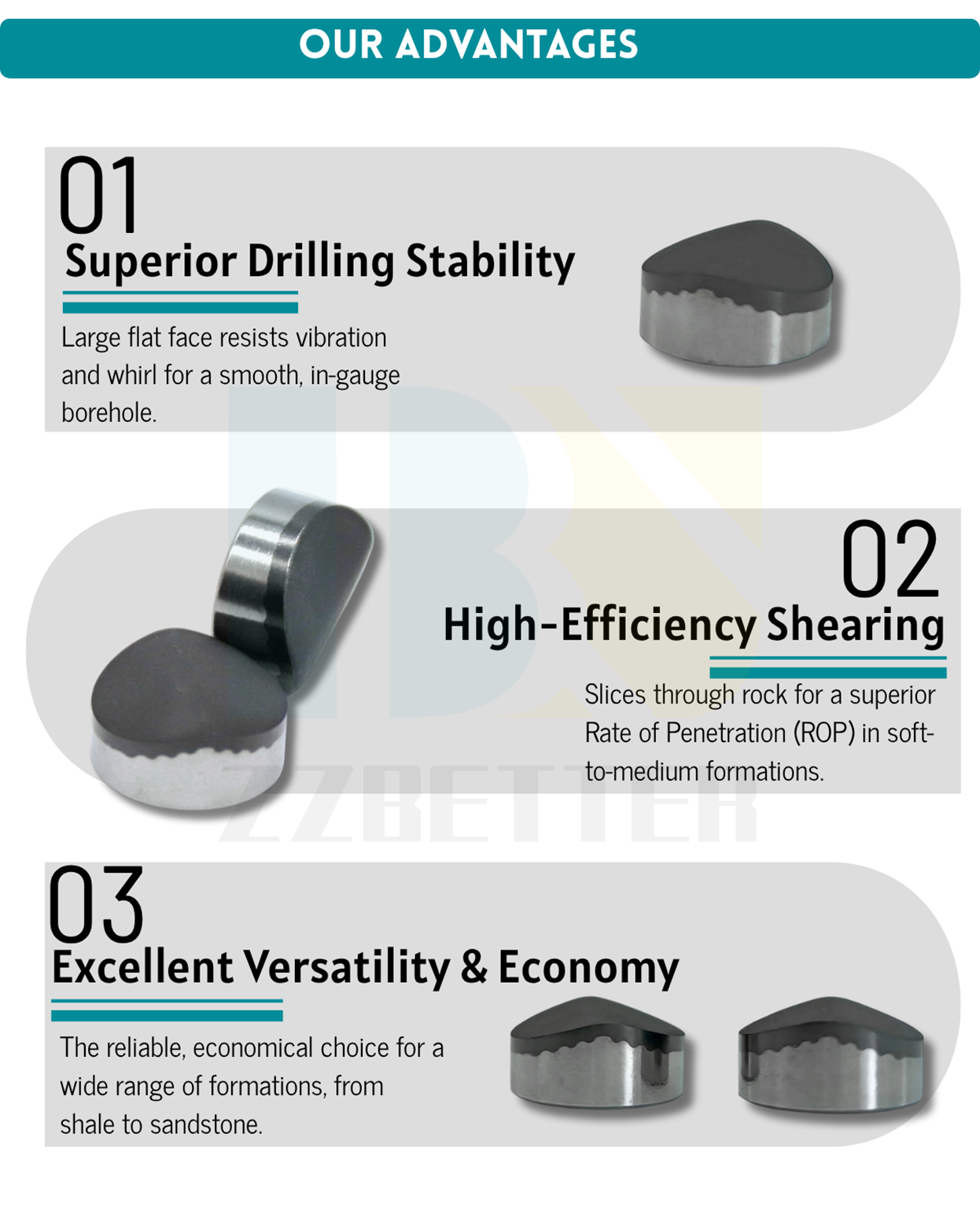

The defining feature of PDC Ridged Cutters is their dual-action cutting and cleaning capability, which directly translates to sustained performance in soft to medium-hard, abrasive formations. Their core advantages are threefold. First, they provide Enhanced Cutting Efficiency, as the ridges concentrate the cutting force, resulting in a more aggressive shearing action compared to a flat surface, which leads to a faster Rate of Penetration (ROP). Second, they offer Superior Thermal Management, as the grooves drastically improve the removal of cuttings from the cutter face, preventing bit balling and ensuring the cutter runs cooler, thereby extending its service life. Finally, they deliver Optimized Performance in Abrasive Formations, where the combination of efficient cutting and continuous self-cleaning provides a distinct advantage over standard cutters that are prone to packing and overheating.

Our uniquely designed cutting element geometry enhances cutting efficiency and the durability of PDC bits. This enables our PDC bits to drill at a higher Rate of Penetration (ROP) and achieve greater footage, thereby saving drilling time and costs.

ZZBETTER is excited to help you discover how our high-quality diamond solutions can enhance your work. Don't hesitate to reach out if you have questions or want to learn more about our PDC cutters.

ZZBetter: Your Leading PDC cutters Manufacturer & Supplier

-----------------------------------------------------------------------------------------------------------------------------

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China, 412000

Tel:0086 73128705418

Phone:0086 13647338188

Fax:0086 073128510897

Email:PDC@drillbetter.com

Whatsapp: 008618173362360