Superior Drilling Performance Drillbetter PDC Cutter Series

Cutter Type: PDC

Application: PDC drill bit, DTH drill bit, Diamond pick, Anchor bit, Core bit

Advantages: Enhanced wear resistance, impact resistance, Superior formation adaptability

Quality Certification: ISO 9001

Request a quote for detailed information (MOQ, price, delivery)

Superior Drilling Performance Drillbetter PDC Cutter Series :

From standard cutters to custom drilling solutions, we provide the industry's most reliable PDC products for extreme conditions.

There are different kinds of drillings. That's why we engineered specialized PDC cutter geometries—each optimized for specific formation characteristics. Stop compromising with one-size-fits-all cutters. Start drilling smarter.

Different types, one purpose: Optimazing performance

PDC cutters aren't just about hardness, geometry matters.The right cutter shape can mean the difference between smooth drilling and premature failure. Our series gives you the right tool for every job underground.

1. PDC Flat Cutter

For soft to medium formations

When you're drilling consistent shale or clay, you need reliable, predictable performance. Our Flat Cutter delivers exactly that—balanced wear resistance and cutting efficiency for uniform formations where stability is key.

Ideal for: Shale, clay, soft sedimentary rock

2. PDC Spherical Cutter

For hard, abrasive layers

Hitting hard sandstone or quartzite? Conventional cutters can fracture under impact. The spherical design distributes stress evenly, handling abrasive formations that would quickly wear flat surfaces.

Ideal for: Sandstone, quartzite, hard abrasive strata

3. PDC Conical Cutter

For directional drilling control

Steering through curves or maintaining angle in directional wells requires precise side cutting. The conical profile reduces torque while providing the side cutting capability needed for controlled directional work.

Ideal for: Directional sections, curve drilling

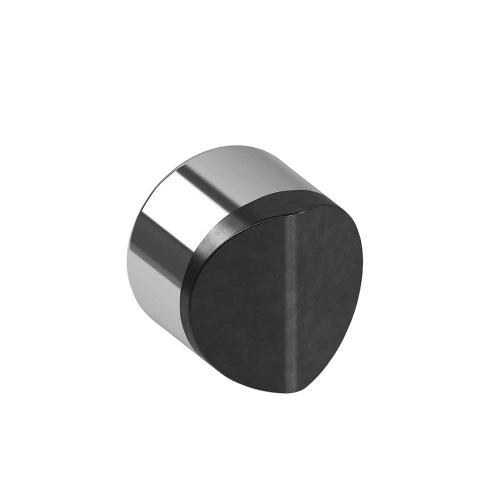

4. PDC Ridged Cutter

For fast penetration in softer zones

When geology allows for aggressive drilling, ridges channel cuttings away efficiently, preventing balling and reducing heat buildup. Drill faster without sacrificing cutter life.

Ideal for: High-ROP sections, softer homogeneous formations

5. Shaped PDC Cutter

For unusual or mixed formations

Some formations don't fit the textbook. When you encounter volcanic intrusions, fractured zones, or unpredictable geology, our custom-shaped cutters provide solutions for your specific challenge.

Ideal for: Complex geology, special applications

Formation Type | Primary Challenge | Recommended Cutter |

Soft Shales | Balling, poor cleaning | Flat Cutter |

Hard Sandstones | Rapid wear, impact damage | Spherical Cutter |

Directional Wells | Poor steerability, high torque | Conical Cutter |

High-ROP Zones | Heat buildup, premature failure | Ridged Cutter |

Complex Geology | Unpredictable, variable | Shaped Cutter |

ZZBetter: Your Leading PDC cutters Manufacturer & Supplier

-----------------------------------------------------------------------------------------------------------------------------

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China, 412000

Tel:0086 73128705418

Phone:0086 13647338188

Fax:0086 073128510897

Email:PDC@drillbetter.com

Whatsapp: 008618173362360