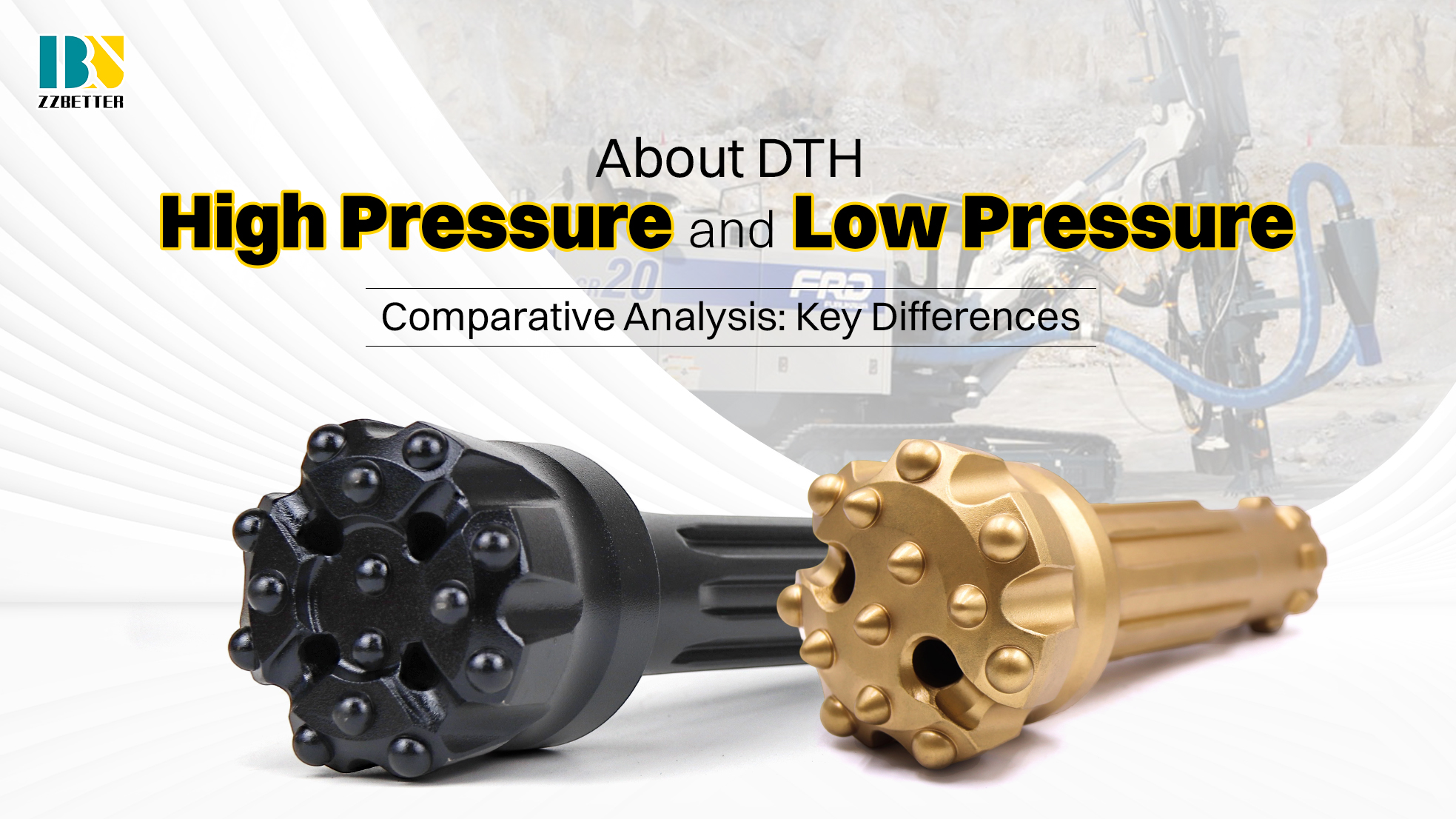

Comparative Analysis: Key Differences

| Feature | Low/Medium-Pressure DTH | High-Pressure DTH |

| Operating Pressure | 100 - 250 psi (7 - 17 bar) | 250 - 350+ psi (17 - 24+ bar) |

| Impact Energy | Lower | Significantly Higher |

| Penetration Rate | Good in soft to medium rock | Excellent and superior in hard, abrasive rock |

| Initial Cost | Generally Lower | Higher |

| Operating Cost | Lower (standard compressors) | Higher (requires high-output compressors) |

| Primary Applications | Water wells, construction, anchors | Large-scale mining, heavy civil engineering |

| Rock Competency | Soft to Medium | Medium to Extremely Hard and Abrasive |

The choice between a High-Pressure and a Low/Medium-Pressure DTH system is not a matter of one being universally better, but of selecting the right tool for the job. For general-purpose drilling in softer formations or where budget and compressor availability are constraints, Low-Pressure systems offer exceptional value and reliability. However, when facing the formidable challenge of hard, deep rock in high-stakes mining and construction, the superior impact energy and faster penetration rates of High-Pressure DTH systems make them the undisputed champion, ultimately leading to lower cost-per-meter drilled and higher overall project productivity. Understanding this fundamental distinction is the first step toward optimizing any drilling operation.

Unlike tungsten carbide DTH bits, it is crucial to clarify the primary distinction. PDC DTH bits are not fundamentally classified by air pressure like traditional carbide DTH bits. The High-Pressure and Low-Pressure classification is inherent to the DTH hammer itself (e.g., DHD340 vs. CIR series), which dictates the operating pressure and impact energy. A PDC bit is a tool that can be mounted on either a High-Pressure or a Low-Pressure hammer, provided the thread connection and size are compatible. The revolutionary difference lies in the rock-breaking mechanism. Traditional carbide bits are percussion tools; they fracture rock through repeated, high-energy impact. In contrast, a PDC bit is a shear tool. Its sharp, table-shaped PDC cutters—a layer of synthetic diamond bonded to a tungsten carbide substrate—scrape or shear the rock surface continuously under the weight and rotation from the drill string, all while being energized by the hammer's percussion. This combination of shear and percussion makes it uniquely effective.

Studying tunsten carbide DTH bits will help us to understand the drilling system better, so we can design better performance PDC cutters and PDC DTH bits. We can improve on both material composition, producton technology and the bit dsign. Want to now more aout PDC welcome to visit www.drillbetter.com, or emaill to PDC@drillbetter.com.