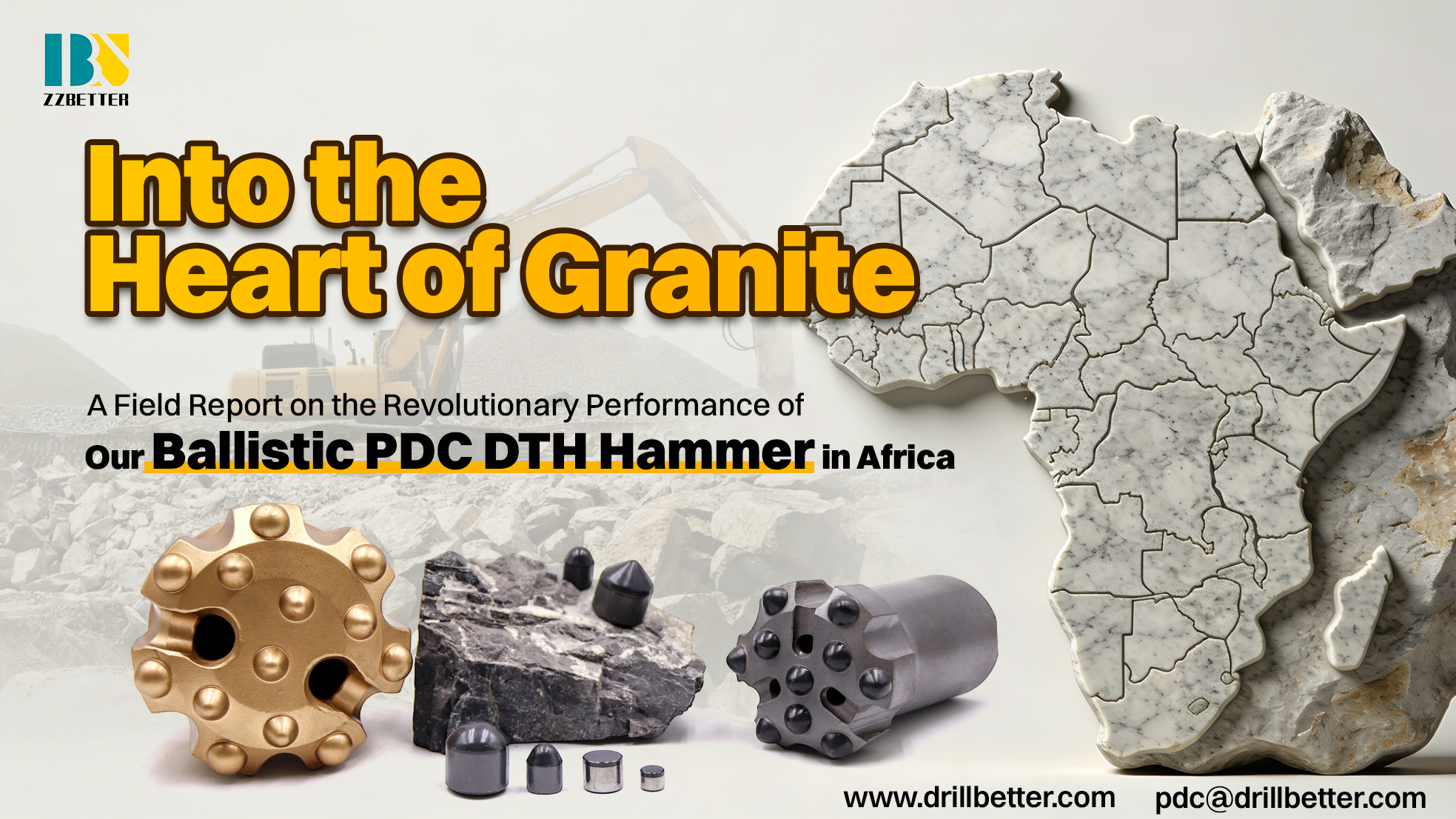

The relentless pursuit of efficiency and durability in hard rock drilling has led our technical team on a journey to the challenging terrains of Africa. Here, amidst some of the world's most abrasive granite formations, we conducted a rigorous field evaluation of our latest innovation: the 115mm Down-The-Hole (DTH) hammer equipped with proprietary Ballistic PDC cutters. The mission was clear: to push the boundaries of performance in deep, hard rock applications. The results, captured in the raw data from a drill site piercing through granite to depths exceeding 1100 meters, are nothing short of transformative.

Confronting the African Granite Challenge

Granite, with its high compressive strength and abrasive quartz content, has long been the ultimate proving ground for drilling technology. Traditional approaches, often relying on tungsten carbide button bits, involve a constant battle against rapid wear and diminishing penetration rates, leading to high operational costs due to frequent bit changes and downtime. Our objective was to demonstrate that PDC (Polycrystalline Diamond Compact) technology, once considered primarily for softer formations, could be engineered to dominate this hard rock environment through advanced cutter design and robust system integration.

The Test Parameters: A Side-by-Side Comparison

The field trial was designed for a direct, real-world comparison under identical conditions:

Tool: 115mm DTH Hammer.

Bit Type: Ballistic PDC Cutter Bit vs. Standard Tungsten Carbide Button Bit.

Drilling Depth: A sustained run from surface to 1100-1200 meters in continuous granite.

Key Metric: Drilling speed per 3-meter interval.

The data spoke with compelling clarity:

Our Ballistic PDC Drill Bit achieved an average drilling speed of 6.30 seconds per 3 meters.

The Tungsten Carbide DTH Bit averaged 8.30 seconds per 3 meters.

Analysis: Decoding a 23.8% Leap in Performance

At first glance, a difference of 2 seconds per interval might seem modest. However, extrapolated over a 1200-meter drill run, the implications are profound. Our PDC bit completed the interval 23.8% faster than the carbide bit. This performance delta translates into substantial operational advantages:

Unprecedented Rate of Penetration (ROP): The consistent, shearing action of the Ballistic PDC cutters through the granite significantly reduces the specific energy required for rock fragmentation. Unlike the crushing/chipping mechanism of carbide buttons, the PDC cutters slice through the grain structure, maintaining a superior ROP that does not drastically degrade over time.

Remarkable Consistency and Longevity: The most significant finding was not just the initial speed, but the sustained performance. While carbide bits typically exhibit a gradual but steady decline in ROP as the buttons wear and flatten, our PDC bit maintained its aggressive cutting profile throughout the marathon depth. This consistency is a hallmark of the diamond’s extreme wear resistance, suggesting a dramatically extended bit life. Fewer trips out of the hole for bit changes mean drastically reduced non-productive time.

Total Cost of Ownership (TCO) Revolution: The combination of faster drilling and longer service life fundamentally alters the economics of hard rock drilling. Reduced rig time saves on fuel, labor, and machine wear. The need for fewer bits per project lowers direct consumable costs and logistics overhead. In remote African locations, where supply chains can be complex, the reliability and longevity of a single tool become invaluable strategic assets.

Superior Borehole Quality: The shearing action of the PDC cutters often produces a smoother borehole wall compared to the more percussive carbide bits. This can lead to reduced reaming time, easier casing installation, and potentially lower demands on drilling fluids.

Conclusion: Redefining the Benchmark for Hard Rock Drilling

This African field trial stands as a resounding validation of our Ballistic PDC DTH technology. Confronting over a kilometer of unyielding granite, our 115mm hammer system didn’t just compete; it set a new standard. The 23.8% increase in drilling speed, coupled with the promise of exceptional bit life, demonstrates a clear paradigm shift.

We are not merely offering a new bit; we are delivering a comprehensive solution for productivity in the most demanding environments. For mining, geothermal, and deep foundation projects across Africa and beyond, this technology represents a direct path to faster project completion, lower operational risk, and significantly improved bottom-line results. The granite has been our witness, and the data is our testimony. The future of hard rock drilling is here, and it is cutting through the challenge with the unmatched endurance of diamond.

Zhuzhou Better Tungsten Carbide Company has been focusing on PDC cutters and PDC drill bits for over 10 years, and own 4 experienced technicians who are experts in PDC manufacturing, Drill bits manufacturing, PDC bits designing. If you have any standard PDC cutters, PDC drill bits, or non-standard PDC parts to consult, welcome to contact ZZbetter. I believe you can find a proper solution with us.

We will visit more clients in the coming year, we will share our first hand information with you then.

Drilling better with Drillbetter.

Welcome to contact us:

Web: www.drillbetter.com

Email: Pdc@drillbetter.com

Whatsapp: +8618173362360

#PDCDTH #pdcbits #zzbetter #africa #granitedrilling #pdcdrillingtools