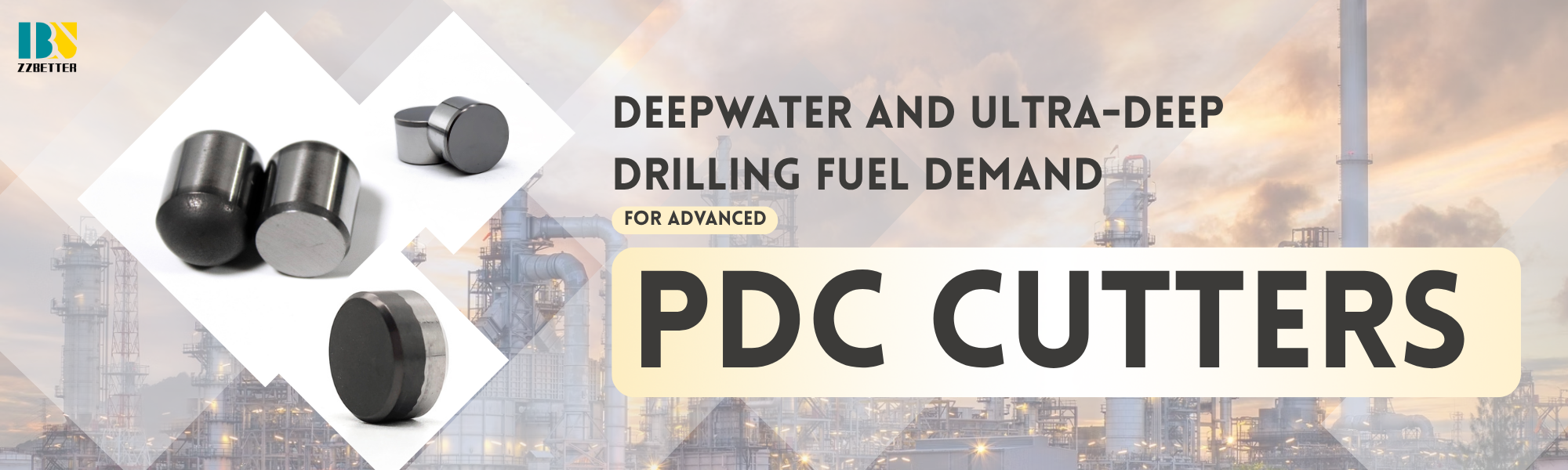

The global energy sector’s push into deepwater and ultra-deep drilling environments is driving unprecedented demand for high-performance polycrystalline diamond compact (PDC) cutters. These challenging applications—characterized by extreme pressure, abrasive formations, and high thermal loads—require cutters that outperform conventional materials. Our company’s advanced PDC cutters are engineered to excel precisely under these conditions, offering distinct advantages that translate into reliability, efficiency, and cost savings for our clients.

One of the standout features of our PDC cutters is their superior thermal stability. Using a proprietary sintering process and advanced diamond table geometry, our cutters maintain their hardness and structural integrity even at temperatures exceeding 350°C. This is critical in deep drilling, where frictional heat can degrade conventional PDC cutters, leading to premature failure. Our products ensure consistent performance in extended drilling operations, reducing non-productive time.

Additionally, our cutters are designed with enhanced abrasion resistance. By integrating uniformly sintered micron diamond grains and an optimized carbide substrate interface, we deliver exceptional wear resistance in silicaceous and other abrasive formations. This results in longer service life, fewer trip changes, and a higher rate of penetration (ROP)—directly lowering cost per meter for operators.

Another key advantage is impact resistance. We employ a novel layered diamond structure and a specially formulated substrate that absorbs and dissipates energy more effectively, reducing the risk of fracture in hard, interbedded formations. This durability is vital in deep water projects where drill string retrieval is time-consuming and expensive.

Our PDC cutters also feature improved hydraulic compatibility, with designs that facilitate efficient cuttings removal and cooling, further enhancing durability and operational efficiency.

For oil and gas companies targeting deep reserves, our PDC cutters provide not just a tool, but a strategic advantage—enabling safer, faster, and more economical drilling. As deepwater exploration grows, our innovation continues to set the benchmark in performance and value.