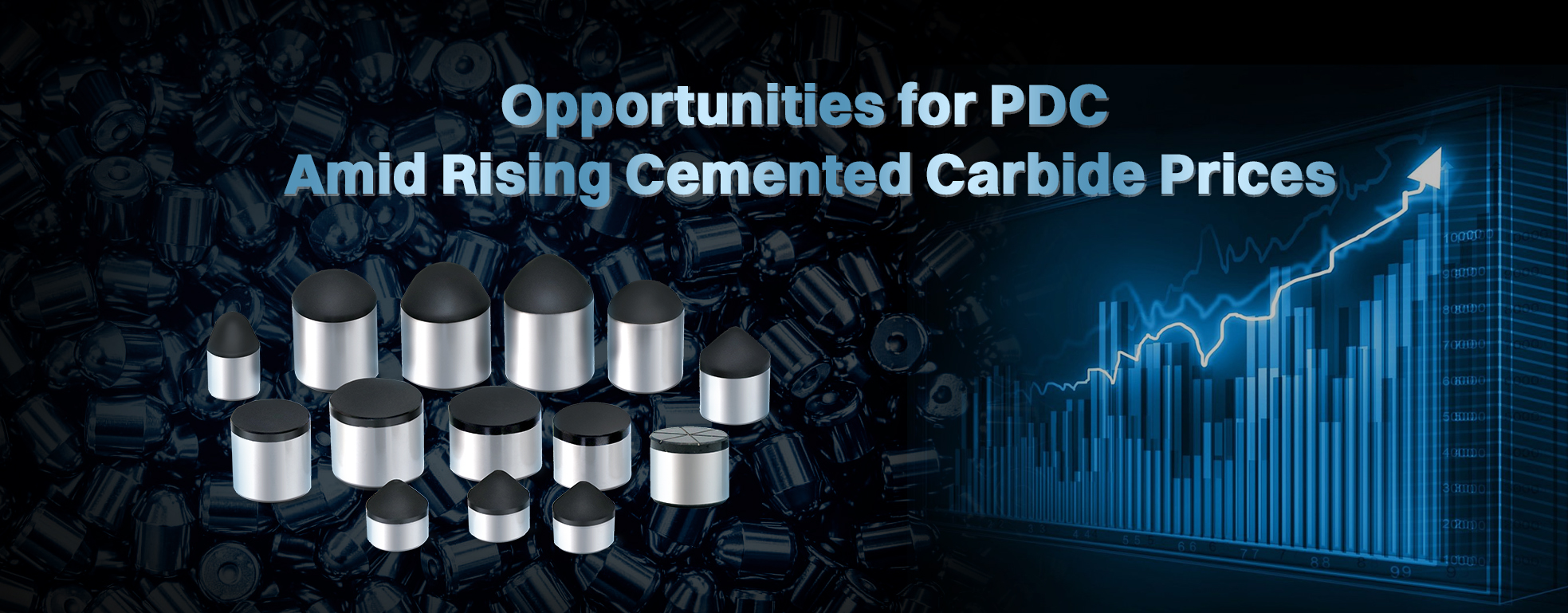

The current market volatility and escalating prices for cemented carbide present a pivotal opportunity for Polycrystalline Diamond Compact (PDC) to expand its application footprint. As an expert in the field, I identify several key industries where PDC is not just a alternative, but a superior, cost-effective solution ready for accelerated adoption.

1.Geological drilling: the fastest win

The most immediate opportunity lies in geological drilling, particularly in soft to medium-hard rock formations. While PDC bits are already established here, high carbide prices make the economic argument for their longer lifespan and superior rate of penetration (ROP) overwhelming. Operators can significantly reduce cost-per-meter by minimizing trip time and bit consumption, directly countering the inflated cost of traditional tungsten carbide insert (TCI) bits.

2.Mining & construction: redefining uptime

Beyond oil and gas, the mining and construction sector is ripe for disruption. PDC-cutters can replace carbide tips in road planning picks, trenching tools, and surface miner drums. Their extreme wear resistance translates to less frequent tool changes, reduced machine downtime, and lower overall operational costs—a crucial advantage when carbide prices are high.

3.Precision machining: throughput without trade-offs

This efficiency is equally valuable in precision machining. PDC inserts for machining non-ferrous metals and abrasive non-metals like composites and ceramics offer dramatically longer tool life than carbide, reducing changeover frequency and improving manufacturing throughput.

4.Woodworking & composites: finish quality that pays for itself

The woodworking and composite materials industry represents a significant growth area. Carbide-tipped saws and router bits wear quickly when processing abrasive materials like MDF, particleboard, or carbon fiber. PDC-tipped tools, though a higher initial investment, last exponentially longer, maintaining a sharper cutting edge for superior finish quality and reduced waste. This directly offsets the cost-paradigm shift caused by expensive carbide.

In conclusion, this period of cemented carbide inflation is not merely a challenge to manage but a strategic catalyst. By aggressively promoting PDC's total cost-of-ownership benefits in drilling, mining, machining, and woodworking, we can catalyze a permanent shift in material selection, solidifying PDC's role as the premier cutting and drilling solution for the future.