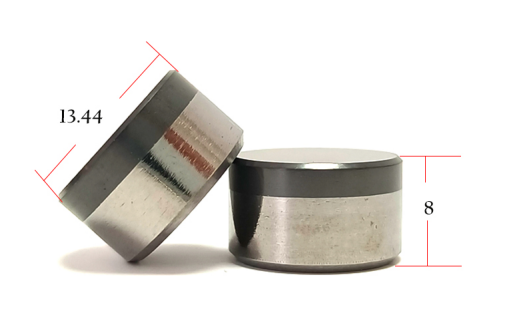

The PDC (Polycrystalline Diamond Compact) flat cutter, specifically the model 1308, is a typical size used for mining and oil drilling. A PDC cutter consists of a layer of synthetic polycrystalline diamond that is integrally bonded to a tungsten carbide substrate under high pressure and high temperature (HPHT). The "1308" designation typically refers to its dimensional specifications—often a 13mm diameter, 8mm height. It is the fundamental cutting element that powers a vast array of high-performance tools.

Primary Applications and Tools

▶Geological drilling : The primary application of the PDC 1308 cutter is overwhelmingly in the geological drilling sector. It is the undisputed champion in the oil and gas industry, forming the cutting structure of PDC drill bits. These bits, studded with multiple 1308 cutters, are capable of drilling through soft to medium-hard rock formations with unparalleled speed and durability compared to traditional roller cone bits. The shearing action of the PDC cutters allows for rapid penetration rates, significantly reducing drilling time and associated costs.

▶Geothermal Well Drilling: Where abrasive and hard formations are encountered.

▶Mining and Mineral Exploration: For obtaining core samples and blast hole drilling.

▶Civil Engineering and Construction: Used in foundation drilling, tunnel boring, and other large-scale projects requiring penetration into rock.

Basically dimension of PDC flat cutters

| Model. (S/M/H) | Diameter (mm) | Height (mm) | Thickness ±0.2 (mm) |

| 1308 | 13.44 | 8 | S: 2.0 M: 2.2 H: 2.4 S: Gauge Protection; Inner Cone M:main cutting teeth, for middle and soft formation H: main cutting teeth, for hard rock formation |

| 1313 | 13.44 | 13.2 | |

| 1608 | 15.88/16.05 | 8 | |

| 1613 | 15.88/16.05 | 13.2 | |

| 1616 | 15.88/16.05 | 13.2 | |

| 1913 | 19.05 | 13.2 | |

| 1916 | 19.05 | 16 | |

| 1919 | 19.05 | 19.05 | |

| Customized sizes according to customer needs are available | |||

A Multitude of Advantages

The widespread adoption of the PDC 1308 cutter is driven by a compelling set of advantages that directly translate into economic and operational benefits.

1. Exceptional Hardness and Wear Resistance: The PDC cutter has phenomenal resistance to abrasive wear, allowing tools to operate for exponentially longer periods without failure or the need for replacement, reducing downtime and tooling costs.

2. High Thermal Stability: PDC cutters are designed to withstand the intense frictional heat generated during cutting and drilling. This thermal resilience ensures consistent performance under extreme conditions.

3. Superior Impact Resistance: The polycrystalline structure of the PDC layer gives it a unique toughness. The random orientation of the diamond grains prevents the propagation of cracks across the entire layer, making the 1308 cutter more resistant to chipping and mechanical shock during operation.

4. High Sharpness and Cutting Efficiency: The cutting edge of a PDC cutter can be manufactured to be extremely sharp, allows for a clean shearing action rather than crushing. This results in faster cutting speeds, lower energy consumption, and a superior quality of the machined or drilled surface.

5. Long Service Life and Cost-Effectiveness: The combination of the above properties culminates in a tool with an exceptionally long service life. Although the initial investment in PDC-based tools is higher than in carbide alternatives, the total cost per meter drilled or per part machined is significantly lower. The reduction in changeover times and increased productivity provide a substantial return on investment.