What's Throttle Plate in oil and gas industry

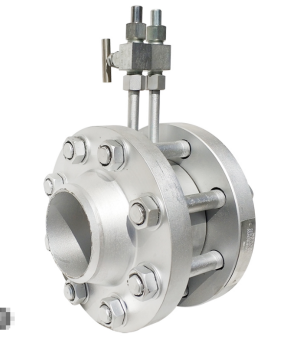

In the oil and gas industry, a "throttle plate" is a component, often a type of valve, is the automated opening and closing of the valve in real-time against a fluid under pressure. While the term is most famously associated with the throttle body in a car engine, it also refers to a type of orifice plate used in flow metering or to control pressure in pipelines, and is a crucial part of the throttling process in both production and control systems.

In flow measurement and control

▶Orifice plate: A throttling orifice plate is a device installed in a pipe to create a restriction. This restriction causes a drop in pressure and is used in flow meters to measure flow rate by sensing the pressure difference across the plate.

▶Pressure regulation: Throttling valves, which contain a throttle plate or similar restricting mechanism, are used to reduce high pressure to a more manageable level or to control the flow rate. This is essential for managing the flow of crude oil and natural gas from the reservoir to processing facilities.

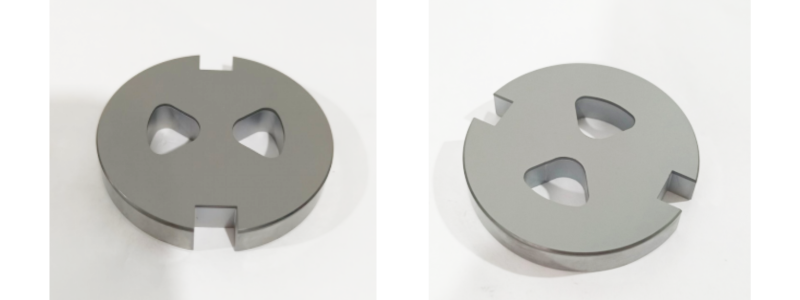

What’s the PDC valve disc

The PDC Valve Disc, also referred to as a PDC Throttle Plate, is a high-performance, nozzle-style check valve designed with an integrated spring mechanism to ensure unidirectional flow control. Its standout feature is a uniquely engineered pulse-damping chamber, which significantly enhances operational stability and durability.

A PDC disc is fabricated through a high-pressure, high-temperature process that sinters a layer of synthetic diamond crystals—one of the hardest known substances on earth—onto a tungsten carbide substrate. The result is a composite material that possesses a unique combination of properties essential for survival in extreme environments.

Ideal for harsh industrial environments—including chemical processing and petroleum applications—the PDC valve disc outperforms traditional TC throttle plates where extreme wear, corrosion, and thermal fluctuations are common challenges.

| Name: | PDC Valve Disc ( Diamond VL disc) |

| Application | a key opening and closing component of a throttle valve |

| Dimension | Customized is available |

| Minimum Order Quantity | One piece |

| Price | Negotiable |

| Delivery Time | According to customer requirements |

| Place of Origin | China |

Key Features & Benefits of PDC valve disc

Exceptional Erosion & Corrosion Resistance – Withstands aggressive media and abrasive conditions.

Thermal Shock Resistance – Maintains structural integrity under rapid temperature changes.

Superior Sealing Performance – Ensures a tight seal between the disc and seat for reliable shut-off.

Low Friction Coefficient – Enables smooth valve operation and reduces wear during cycling.

High Impact Toughness – Resists mechanical shock and prolongs service life.

Long Service Life – Designed for reliability in demanding applications, minimizing maintenance and downtime.

Upgrade to the PDC Valve Disc for unmatched performance and durability where conventional throttle plates fall short.